How to Ferment Sujuk

Mastering Dry Sausage Fermentation Techniques

Sujuk, a type of fermented dry sausage, offers a rich tapestry of flavors and a unique texture that sets it apart from other charcuterie. Its origins can be traced back to the cuisines of the Middle East and the Balkans. The process of making sujuk involves a careful balance of meat selection, seasoning, fermentation, and drying, all of which contribute to its distinctive taste. Beef, often partially frozen for ease of handling, is the common choice of meat for sujuk. The meat is ground, mixed with spices, and then introduced to beneficial bacteria that facilitate the fermentation process.

Fermentation is a crucial step in sujuk making, where the meat mixture is allowed to undergo a controlled microbial growth, which imparts tangy flavors and aids in preservation. This occurs at specific humidity and temperature conditions, often at room temperature ranging from 24 to 48 hours, depending on the recipe. The fermented meat is then stuffed into casings and hung in a controlled environment to dry. This drying stage can last from several days to a week and is essential for developing sujuk's firm texture and concentrated flavor.

Sujuk serves not only as a testament to the culinary traditions from which it hails but also as a robust ingredient in various dishes. The final product is aromatic and versatile, adding depth to breakfast dishes, stews, and other recipes. In forming sujuk, patience is as much an ingredient as beef and spices, ensuring that the final dry sausage is both safely preserved and brimming with a complexity that can only come from the time-honored practice of fermentation.

Understanding Sujuk

Sujuk is a seasoned, dry, fermented sausage known for its deep flavor and versatility in various cuisines, particularly throughout Eastern Europe and the Middle East.

History and Origin

Sujuk originated in the regions of the Middle East and the Balkans, where it has a long-standing history as a preserved meat product. Its production has historically been a means to extend the shelf life of meats, especially prior to the modern era of refrigeration. The precise origin is difficult to pinpoint due to the widespread nature of sujuk and its variations under different names across multiple countries.

Cultural Significance

The cultural significance of sujuk cannot be overstated. It is an integral part of culinary traditions and often makes its appearance during breakfasts, in sandwiches, and in various cooked dishes. In different countries, sujuk serves not only as a staple food but also as a representative of national identity and pride. Its recipes and preparation methods are often passed down through generations, preserving the link between food and cultural heritage.

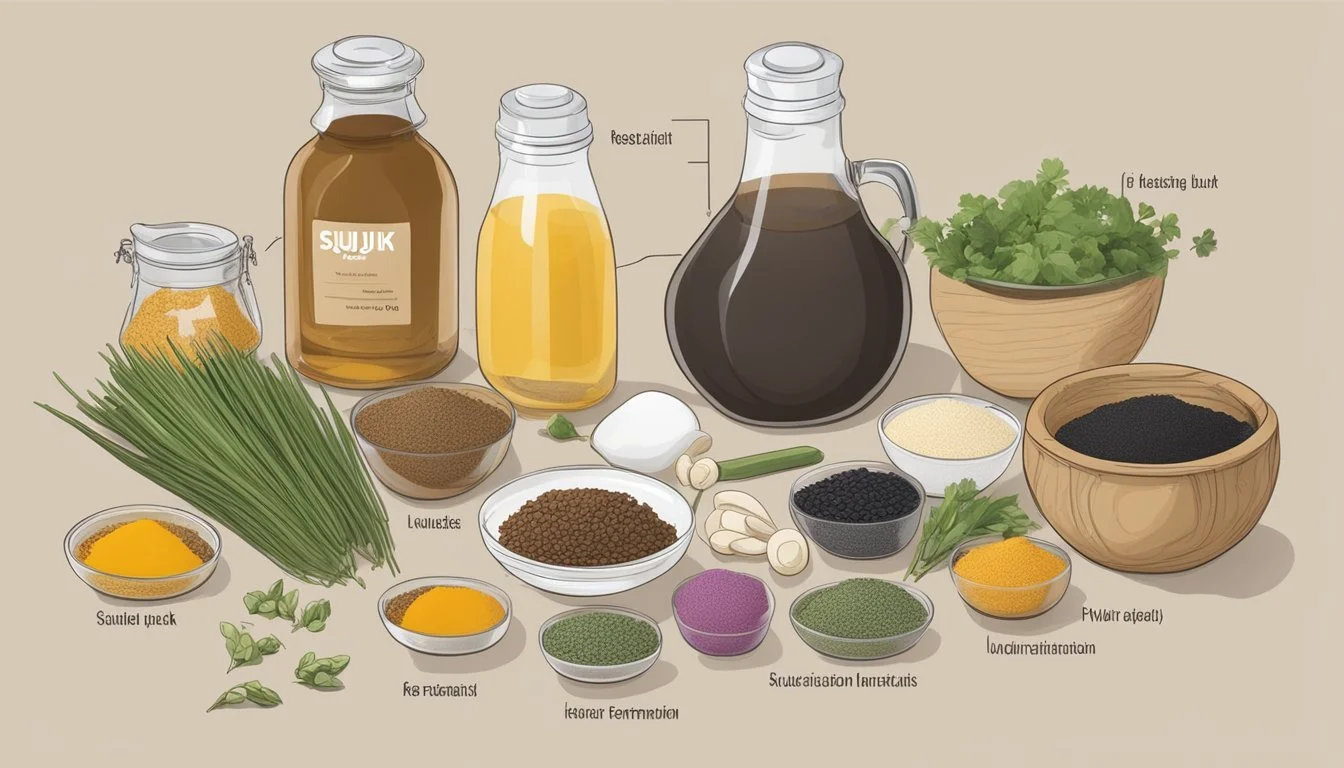

Ingredients and Supplies

The success of fermenting Sujuk lies in the careful selection of quality ingredients and the appropriate supplies. This section details the specific meats, spices, and equipment necessary for the fermentation process.

Meat Selection

The choice of meat is crucial, as it is the foundation of Sujuk. Typically, beef is preferred for its rich flavor and fat content, which should ideally be around 20-30%. However, other meats like pork or lamb can also be used. It's essential to partially freeze the meat before grinding to ensure it remains cold, maintaining its texture and facilitating the grinding process.

Beef: Preferred Cut - Chuck, Round or Brisket, Fat Content - 20-30%

Pork: Preferred Cut - Shoulder, Fat Content - 20-30%

Lamb: Preferred Cut - Shoulder, Fat Content - 20-30% (if used)

Selecting Spices and Herbs

Spices and herbs define Sujuk's distinctive taste. A combination of kosher salt, black pepper, cumin, coriander, and garlic is typically used to impart the classic flavor. It's essential to mix these spices in the right ratios. Exact measurements depend on the meat weight, but a guideline is to use about 2.5% of the meat's weight in salt, including both kosher and curing salts.

Kosher Salt: Importance - Enhances flavor, aids fermentation, and preservation, Typical Quantity - 2.5% of meat weight

Black Pepper: Importance - Adds depth and spiciness, Typical Quantity - To taste

Cumin: Importance - Signature flavor for Sujuk, Typical Quantity - To taste

Coriander: Importance - Adds a warm, citrusy flavor, Typical Quantity - To taste

Garlic: Importance - Offers pungency and complements other spices, Typical Quantity - To taste

Casing and Additional Supplies

Casing selection is vital, and hog casings are common for Sujuk because of their size and durability, with diameters ranging from 28-32mm. Important additional supplies include:

Cure #1 or Cure #2: Ensures safety by preventing harmful bacteria growth

Starter culture: Usually a lactobacillus species, lowers pH for safe fermentation

Dextrose: Serves as food for the starter culture

Meat grinder: For grinding meat into the desired consistency

Sausage stuffer: To fill the casings with the seasoned meat mixture

Sausage pricker: To remove any air pockets in stuffed sausage

UMAi Dry: A possible casing alternative for dry-aging without the need for a controlled environment

For sanitation, an iodophor sanitizer is recommended for cleaning all equipment. It is critical to maintain a sanitary work area to avoid contamination and ensure a safe fermentation process.

Preparation Process

In the creation of Sujuk, meticulous preparation ensures the quality and safety of the dry sausage. This involves thoroughly cleaning equipment, carefully grinding and mixing meat with ingredients, and properly filling casings.

Cleaning and Sanitizing

Before beginning the process of making Sujuk, one must thoroughly clean and sanitize all surfaces, tools, and equipment. This includes grinders, sausage stuffers, cutting boards, and utensils. Clean with hot soapy water and follow with a sanitizer solution, typically a dilution of bleach and water or a food-safe sanitizer, to eliminate any contaminants that could spoil the sausage or be harmful to consumers.

Meat Grinding and Mixing

Select high-quality meat and partially freeze it to maintain an ice cold temperature, making it easier to grind. They should use a grinder to process the meat through a medium size plate (3/16" or 4.5 mm). After grinding, they should mix the meat with the necessary spices, ingredients like sugar, and the mold 600 culture, which helps in the fermentation process. It is critical to ensure the ingredients are evenly distributed throughout the meat.

Filling Casings

Once the meat and spices are adequately mixed, they should stuff the mixture into casings using sausage stuffers, taking care not to overfill. The casings size typically ranges from 28-32mm, ensuring an even thickness for the Sujuk. After stuffing, they must expel any air pockets to prevent spoilage and promote even drying during fermentation. They then hang the sausages in a controlled environment, perfect for the fermentation to commence.

Fermentation and Curing

The fermentation and curing processes are critical for producing the distinctive flavor and safety of Sujuk. Precision with time, temperature, and specific ingredients like starter cultures is necessary to achieve the desired quality.

Curing and Spices Introduction

Before fermentation, curing the meat is an essential step that enhances flavor and ensures safety. Cure #1, also known as Prague Powder 1, containing sodium nitrite, is commonly used for short-term cured products to inhibit pathogenic bacteria. For Sujuk, a combination of curing salts, including Cure #2 which contains both sodium nitrite and sodium nitrate, can be used for its longer curing time. Spices are mixed with the meat providing the Sujuk with its unique taste profile.

Curing ingredients:

Cure #1 (for short-term curing)

Cure #2 (for long-term curing)

Other spices (varies by recipe)

Fermenting the Sausage

Fermenting the sausage is the next step, where sugar is used to feed starter cultures that produce lactic acid, lowering the pH of the sausage to stabilize and preserve it. The fermentation process should occur at controlled room temperature for 24 to 48 hours to achieve the correct acidity. For proper fermentation, conditions such as temperature (approximately 20°C or 68°F) and humidity (around 80% RH) should be closely monitored and maintained. Once fermented, the Sujuk is then dried under controlled conditions to develop its characteristic texture and intensity of flavor.

Parameters for fermentation:

Temperature: ~20°C (68°F)

Humidity: ~80% RH

Duration: 24 to 48 hours

pH goal: < 5.3

Post-fermentation, monitoring continues as the sausage cures, focusing on keeping an optimal temperature of around 15°C (59°F) and humidity of 75%, which might vary slightly, ensuring the fat in the sausage does not go rancid, and allowing the flavors to mature.

Drying and Aging

After the initial fermentation phase, sujuk enters the critical drying and aging stage, which is essential for developing its flavor and safety. Properly managed drying conditions ensure that sujuk achieves the desired texture and weight loss without compromising quality.

Weight Loss and Texture Control

During the drying stage, sujuk gradually loses moisture, which is a key indicator of the sausage's progression. Optimal weight loss is typically between 30% to 40% of the sausage's initial weight. This process must be carefully monitored, as insufficient weight loss can lead to spoilage, while too much can result in an overly dry product. The texture of the sausage should feel firm but not hard, indicating that the dry-cured process is on track.

To achieve the correct texture:

Recording the starting weight of the sausage allows for accurate tracking of weight loss.

Using a precise scale, one should regularly weigh the sausages to monitor changes and ensure they are within the target weight loss.

Monitoring and Adjusting Conditions

The environment within the drying chamber or curing chamber plays a pivotal role in the quality of dry-cured sausages. Maintaining a consistent temperature around 55°F (13°C) and humidity at 80% rH is generally recommended for optimal results. These conditions help to control the sausage's a_w (water activity), prevent unfavorable bacteria growth, and allow beneficial mold to develop on the casing, contributing to flavor and safety.

To maintain the ideal drying environment:

A hygrometer is used to measure humidity, and adjustments are made as needed to remain within the acceptable range.

A reliable thermometer keeps track of the temperature within the chamber, ensuring it stays consistent.

By rigorously supervising the drying and aging conditions, one can produce sujuk that is properly fermented, safe to consume, and rich in nutrition and traditional flavors.

Storing and Preservation

Proper storage and preservation are crucial for maintaining the quality and safety of fermented sujuk. The process of fermentation preserves the sausage, enhancing both its flavor and nutritional profile, while refrigeration ensures the product remains safe for consumption over time.

Refrigeration and Packaging

After fermentation, sujuk should be refrigerated at temperatures below 40°F (4°C) to slow down any bacterial growth and preserve its quality. The sausage should be wrapped in paper or packed in vacuum-sealed bags to protect against contaminants and preserve its flavor. Proper packaging not only extends the shelf life but also maintains the nutritional integrity of the sausage – including the beneficial lactic acid produced during fermentation.

Shelf Life and Safety

The shelf life of fermented sujuk typically ranges from several weeks to a few months when stored correctly in the refrigerator. The presence of lactic acid functions as a natural preservative, inhibiting the growth of harmful bacteria and enhancing safety. It is essential to monitor the sausage for any signs of spoilage, such as off-odors or unusual textures, and to consume it before the expiration date to ensure safety. Always handle with clean utensils and maintain hygienic conditions to prevent cross-contamination.

Cooking and Serving Suggestions

Once sujuk has been properly fermented and cured, it presents a rich tapestry of flavor and texture, ideal for a range of culinary applications. Cooks should emphasize its robust taste profile and versatile nature in the kitchen.

Preparation Techniques

Properly prepared sujuk can be consumed raw, considering it is fully cured. The sausage should be sliced thinly to fully appreciate its complex flavor and firm texture. For cooking, one can sear or grill slices of sujuk over medium heat until both sides are slightly crisp, generally taking between 2-3 minutes per side.

Grilling: Achieve a smoky note by grilling the sujuk, enhancing its existing aromatic spices.

Pan-frying: In a non-stick skillet, sujuk can be crisped on the edges, melding the flavors with the fat rendered out during cooking.

Pairing and Recipes

The bold, spicy profile of sujuk pairs well with milder ingredients that can absorb and complement its intense flavors.

Sujuk and Eggs: A classic Middle Eastern breakfast whereby sujuk is cooked until crisp before adding eggs to the pan and cooking to preference.

Sujuk Pizzas: Use thin slices as a topping on pizza for a unique twist, balancing with creamy cheeses like mozzarella.

Textural Contrast: Serve with crusty bread or alongside creamy dips to contrast the chewy texture of the sausage.

Wine Pairing: A glass of full-bodied red wine like Shiraz can match sujuk's exotic and vivid taste, making an excellent gastronomic combination.

Troubleshooting Common Issues

In crafting sujuk, precision in fermentation, and careful balancing of flavor and texture are paramount. When one encounters difficulties, they must assess safety, monitor bacterial cultures and pH levels, and adjust temperature and humidity to ensure optimal results.

Fermentation Problems

Fermentation issues often arise from temperature and humidity control. The ideal fermentation temperature for sujuk should be maintained between 20°C to 30°C (68°F to 86°F), with humidity hovering around 80-90%. Should the sausage fail to ferment correctly:

Temperature Control: One must ensure a stable environment. Fluctuations can be detrimental to beneficial bacteria needed for fermentation.

Humidity: If the air is too dry, the sausage can harden prematurely, inhibiting proper fermentation. A controlled environment like a fermentation chamber can stabilize conditions.

Safety and Bacteria: The use of quality starter cultures is critical. These beneficial bacteria help lower the pH to a safe level, usually below 5.3, which is a sign of proper fermentation.

Texture and Flavor Adjustments

The balance of fat, spices, and the curing process are vital to the final texture and flavor of sujuk. Problems and adjustments may include:

Fat Content: Too much or too little fat can drastically alter texture. A ratio of about 20-30% fat to meat is recommended for both the mouthfeel and flavor.

Flavor Profile: The mix of spices should be carefully measured. Adjustments may be needed if the flavor is too bland or too overwhelming. In such cases, one should make minor, incremental changes to the spice blend in future batches.

PH Monitoring: An ideal pH range for sujuk is between 4.6 and 5.2. A pH that is too high indicates insufficient acidification and could lead to safety concerns, while a pH that's too low can result in a harsh flavor profile.

By addressing these issues with precision, one ensures the production of a safe and palatable sujuk.

Tools and Equipment

When making Sujuk, certain tools are essential for the process, while others can enhance precision and efficiency. Proper equipment ensures the quality and safety of the dry sausage.

Essentials for Sujuk Making

Sausage Stuffer: A must-have to fill casings with the prepared meat mixture precisely.

Meat Grinder: Used to grind the meat and fat to the desired consistency. For the best texture, a medium size plate (3/16" or 4.5 mm) is recommended.

Sausage Pricker: This tool is important to prick out any air pockets after stuffing the sausage to prevent spoilage.

Controlled Environment Equipment: This includes items such as Inkbird controllers for maintaining the required temperature and humidity.

Thermometer and Hygrometer: Instruments like the Mk4 Thermapen help monitor the temperature, while a hygrometer checks humidity levels.

PH Meter: The Apera PH meter with Bluetooth is essential to ensure the proper acidity level of the sausage is achieved during fermentation.

Table 1: Essential Tools

Sausage Stuffer: Use - Filling casings

Meat Grinder: Use - Grinding meat and fat

Sausage Pricker: Use - Removing air pockets

Inkbird Controllers: Use - Temperature and humidity control

Mk4 Thermapen: Use - Temperature measurement

Apera PH meter: Use - Monitoring acidity levels

Optional Tools

Additional tools can provide further control or make the process easier.

Dehumidifier: Can assist in maintaining the ideal humidity levels, especially in damp environments.

Ultrasonic Humidifier: The Eva Dry 1100 Cool Mist Ultrasonic Humidifier helps maintain requisite moisture levels during drying.

Table 2: Optional Tools

Dehumidifier: Use - Reducing humidity

Eva Dry 1100: Use - Maintaining humidity

By equipping yourself with these tools and appliances, you can embark on creating Sujuk with accuracy and confidence, understanding the critical role of each component in the fermentation and drying process.

Advanced Techniques

When crafting sujuk, advanced techniques involve meticulous attention to the interplay of flavors, textures, and fermentation processes. Mastering these elements allows for the creation of signature varieties that stand out for their unique qualities.

Experimenting with Flavors and Textures

Flavor Development: A key factor in the art of sujuk making is the selection and combination of seasonings. Experimenting with different spices such as cumin, sumac, and garlic can profoundly affect the final product's taste profile. Incorporating exotic spices or introducing infusions of regional herbs can distinguish one's sujuk from the traditional offerings.

Spice Ratios:

Start with a base ratio (e.g., 1 part cumin to 0.5 part sumac) and adjust incrementally.

Use a scale for precise measurement and consistency.

Texture Refinement: Texture is as crucial as flavor. A course, cold grind ensures fat is evenly dispersed without smearing. This impacts the sausage's mouthfeel and, in conjunction with proper fermentation and drying, the snap of the casing.

Cold Smoking: Adding this step imparts a subtle smokiness and can affect texture.

Use a cold smoke technique to avoid cooking the sausage, typically maintaining a temperature below 30°C (86°F).

Creating Signature Sujuk Varieties

Fermentation Control: The fermentation step is where a sujuk's flavor complexity and safety are established. Proper use of a starter culture is paramount.

Temperature and Humidity:

Ferment at room temperature (20-24°C / 68-75°F) for 24-48 hours.

Dry in a controlled environment (13°C / 55°F and 80% relative humidity) for 3-7 days.

Signature Touches: Creating a signature sujuk variety involves fine-tuning flavor profiles and curing methods. One might consider blending in unique ingredients such as wine or other spirits for an individualized taste, or even varying the types of casings used to alter texture and drying times.

Ingredient Innovations:

Add an unconventional ingredient (e.g., a splash of brandy) during mixing.

Choose casings based on desired diameter and drying characteristics.

Nutritional Information

Sujuk, a type of fermented dry sausage, comes packed with flavors and nutrients. Its nutritional profile offers insights into its health benefits and energy content.

Analyzing Sujuk's Health Benefits

Sujuk contains a variety of nutrients essential for maintaining good health. It's a source of high-quality protein and provides a range of vitamins and minerals, particularly B-vitamins such as B12, which are vital for nerve health and energy production. It also offers minerals like zinc and iron. The fermentation process of sujuk can contribute to a healthier gut microbiome due to the presence of beneficial bacteria. However, sujuk is often high in fat and should be consumed in moderation.

Macronutrients and Calories

When examining the macronutrient composition of sujuk, one finds that it is calorie-dense due to its fat and protein content. Here is a typical nutritional breakdown of sujuk:

Calories: It is relatively high in calories, mainly because of its fat content.

Protein: Sujuk is a rich source of protein, which is important for muscle repair and growth.

Fat: The majority of the calories in sujuk come from fat, which gives it its unique taste and texture. Sujuk contains saturated fats; hence, portions should be controlled.

The processing of sujuk includes curing it with nitrites, which help to preserve the sausage and give it a distinctive flavor. However, a high intake of nitrites should be avoided, as there is some evidence to suggest it may be harmful over time. Consumers looking to include sujuk in their diet should be aware of its nutritional content and consider it as part of a balanced diet.

Glossary of Terms

Starter Culture

A starter culture is a preparation of microorganisms, typically bacteria, used to initiate the fermentation process in sausage making. It assists in flavor development, preservation, and ensuring food safety by lowering the pH of the sausage.

Casings

Casings are the outer layers of sausages made from animal intestines or synthetic materials. They hold the meat mixture together and contribute to the final shape and texture of the sausage.

Fermentation

Fermentation refers to the biochemical process where sugars like dextrose are converted by bacteria into lactic acid. This process decreases the sausage's pH, enhancing flavor and preservation.

Curing

Curing is the process of preserving and flavoring the meat through the application of salt, nitrates, or sugar. It can be achieved through dry-curing or wet-curing methods.

pH

pH is the measure of acidity or alkalinity. In sausage making, the goal is to achieve a pH of around 4.6–5.0 for optimal safety and flavor profile.

a_w (Water Activity)

The a_w or water activity level indicates the available free water in the sausage for microbial growth. Lower a_w levels contribute to longer shelf life and reduced bacterial growth.

Humidity

Humidity is critical in the drying phase of sausage making, typically maintained at 80% relative humidity (rH), to ensure steady drying without case hardening.

Starter Cultures

Starter cultures are critical in sausage fermentation, providing the necessary bacteria to ensure controlled and consistent fermentation outcomes.

FLC (Fermentable Lactic Culture)

An FLC or fermentable lactic culture contains selected bacteria strains used to ferment sugars into lactic acid, which then effectively reduces the sausage's pH.

Dextrose

Dextrose is a simple sugar used as a food source for the fermentation bacteria within the sausage, aiding the reduction of pH and contributing to the development of the characteristic tangy flavor.