On-Farm Meat Processing, Butchering and Slaughter in Delaware

Your Comprehensive Guide

On-farm meat processing is an emerging approach to meat production that affords farmers in Delaware greater control over the quality and distribution of their products. This method of slaughtering and butchering livestock directly on the farm presents an opportunity to streamline the traditional path from farm to table. By overseeing the processing phase, Delaware farmers can ensure that their meat meets high standards of quality and safety, while also potentially reducing transportation costs and stress on the animals, which can have an impact on meat quality.

With the advent of mobile slaughtering units and on-farm facilities, Delaware is witnessing a shift in the meat processing industry. These mobile units travel from farm to farm, enabling the processing of meat to state-inspected standards, providing farmers with the flexibility to operate within local regulations while reaching consumers directly. Farmers must be well-prepared for the arrival of such units to maximize efficiency and adhere to food safety regulations.

These developments cater to a community that values locally sourced and handled meats, creating a specialized market for Delaware products. The process also opens up avenues for farmers to establish a niche for themselves by selling meat processed on their own farms, which can foster closer connections with consumers and contribute to the local economy. However, the process is not without its challenges; it requires a significant capital investment and strict adherence to state and federal regulations. Despite the obstacles, the model of on-farm processing marks an impactful evolution in Delaware's agricultural landscape.

Basics of On-Farm Meat Processing

On-farm meat processing in Delaware involves precise steps to transform livestock into market-ready meat products. It requires adherence to regulatory standards to ensure the safety and quality of the meat.

Overview of Meat Processing Steps

Selection and Harvesting: Processors begin by selecting healthy, mature animals ideal for meat production. The harvesting, or slaughter, involves humane techniques to minimize animal stress.

Stunning: Animals are rendered unconscious.

Bleeding: The carcass is bled to remove blood, a critical step for meat quality and safety.

Skinning or De-hairing: Removal of the hide for cattle or skin for pork and poultry.

Evisceration: Removal of internal organs, ensuring no contamination occurs to the carcass.

Splitting: Large animals like beef are split into halves for further cooling and processing.

Cooling and Aging: The carcass is then chilled to prevent bacterial growth. Aging allows enzymes to tenderize the meat, enhancing its flavor.

Processing: The carcass is cut into specific cuts of meat, such as steaks, roasts, and ground products. This step may also involve wrapping and quick freezing for distribution.

Definitions and Key Terms

Meat Processing: The entire process of converting a live animal into edible meat products, including slaughtering, butchering, packaging, and preparing for sale.

Slaughter: The humane killing of livestock for meat. In Delaware, this process must comply with federal and state regulations regarding animal welfare.

Carcass: The body of a slaughtered animal after bleeding and dressing but before cooling and butchering into cuts of meat.

Beef: Refers specifically to meat from cattle. Beef processing includes unique steps such as de-hiding and specific aging requirements for optimal taste and tenderness.

Humane Handling: The methods employed to minimize stress and pain for the animals being processed, a crucial aspect of ethical meat production.

Using this structured approach, Delaware farmers can ensure the meat from their farms is high in quality, safe for consumption, and produced in a manner that respects animal welfare.

Regulatory Framework in Delaware

In Delaware, the regulatory landscape for on-farm meat processing, butchering, and slaughter involves a partnership of federal and state oversight aimed at ensuring food safety and compliance with applicable laws.

USDA vs State-Inspected Facilities

Delaware offers two types of inspection services for meat processing facilities: those inspected by the United States Department of Agriculture (USDA) and those inspected by state authorities. Facilities inspected by the USDA adhere to standards set forth under the Federal Meat Inspection Act. State-inspected establishments, on the other hand, must meet or exceed these federal standards to be awarded the license to operate.

USDA-Inspected Facilities:

Must comply with the Federal Meat Inspection Act

Eligible to participate in interstate and international commerce

State-Inspected Facilities:

Subject to Delaware’s Meat and Poultry Inspection regulations

Approved to sell meat within state borders

Understanding FSIS and CDFA Regulations

The Food Safety and Inspection Service (FSIS) is the federal agency responsible for ensuring that commercial meat and poultry products are safe, wholesome, and correctly labeled and packaged. Delaware's state-inspected facilities must follow FSIS regulations as a foundation and adhere to additional rules as set by the Delaware Department of Agriculture's Food Products Inspection to maintain "equal to" status with federal guidelines.

FSIS Regulations:

Govern all aspects of meat and poultry safety across the country

Facilities must have regular inspections and follow FSIS guidelines

CDFA (Delaware Department of Agriculture) Regulations:

Implement state-specific meat and poultry inspection standards

Oversee Self-Certification Programs to align with FSIS standards

Farm and Farmer Considerations

When delving into on-farm meat processing, Delaware farmers must contemplate the readiness of their operations and understand the specific roles they will undertake. Effective planning and adherence to regulations are critical for both the farm's infrastructure and the farmer's execution of tasks.

Assessing Farm Readiness

Farm Infrastructure: A farm must possess the necessary facilities to handle live animals safely and humanely. This includes:

Adequate space for processing activities

Refrigeration units for meat preservation

Regulatory Compliance: Farmers need to ensure that the farm meets state and federal regulations, which can include:

Zoning laws

Health and sanitation standards

Environmental regulations

Farmer's Role and Responsibilities

Handling Live Animals: The farmer is responsible for the welfare of the livestock, which requires:

Training in humane handling

Knowledge of proper feeding and care

Processing and Butchering: The farmer should have a proficiency in:

Slaughtering techniques that minimize animal stress

Butchering skills to optimize meat yield and quality

Sanitation and Food Safety: Maintaining a clean processing environment to prevent contamination is paramount. Farmers must:

Implement a Hazard Analysis Critical Control Point (HACCP) plan

Regularly clean and sanitize equipment and facilities

By addressing these considerations, Delaware farmers can contribute to the viability and sustainability of local agriculture through on-farm meat processing.

Animal Welfare and Pre-Slaughter Handling

In Delaware, the quality of meat from on-farm butchering and slaughter is closely linked to the welfare and handling of the animals before slaughter. By ensuring low-stress environments and practicing humane handling, farmers can significantly impact both animal health and meat quality.

Reducing Stress for Better Meat Quality

Stress in animals before slaughter can lead to poor meat quality. When animals experience stress, physiological changes such as the elevation of stress hormones can occur, affecting the texture, color, and shelf-life of the meat. For instance, the preslaughter handling of livestock should be aimed at minimizing any stressful stimuli that can lead to conditions like dark, firm, and dry meat, particularly in beef.

Farmers should provide familiar surroundings, gentle handling, and avoid any abrupt changes in the animals' environment. Deliberate measures, such as maintaining a calm atmosphere during transport and allowing animals to become accustomed to the preslaughter environment, can greatly mitigate stress and its detrimental effects on meat quality.

Best Practices for Handling Livestock

To ensure animal welfare during the handling process, there are established best practices that are designed to respect the animal's physical and psychological well-being:

Loading and Transport:

Use non-slip flooring to prevent falls.

Avoid overcrowding to minimize injury and stress.

Lairaging:

Provide adequate space and comfort.

Offer access to water and, if needed, feed.

Movement to Restraint:

Guide animals gently without forceful shouting or prodding.

Utilize well-designed chutes and races to prevent bottlenecks and injury.

Improving animal welfare in on-farm meat processing facilities in Delaware not only adheres to ethical standards but directly influences the quality of meat produced by reducing stress-related meat quality issues. This focus on welfare is a key aspect of modern farming practices and consumer expectations.

Slaughter and Butchering Techniques

On-farm meat processing in Delaware involves specific techniques to ensure the humane and efficient slaughter and butchering of various livestock such as beef, sheep, goats, and poultry. The following subsections detail the methods utilized in the slaughter and butchering processes.

Techniques for Slaughtering Different Livestock

For beef, the most commonly used method is captive bolt stunning, which renders the animal unconscious before slaughter to ensure a humane process. The carcass is then bled out swiftly. Shearing is often the first step in processing sheep, followed by a similar bleeding process. For goats, the method paralleled is throat-slitting, often following stunning for humane considerations. Poultry slaughter involves a step called "shackling," where the birds are hung by their feet before being stunned, usually through an electrified water bath, and then processed through an automated or manual neck cutting.

Beef: Captive Bolt Stunning > Bleeding

Sheep: Shearing > Stunning > Bleeding

Goats: Stunning > Throat-Slitting

Poultry: Shackling > Stunning > Neck Cutting

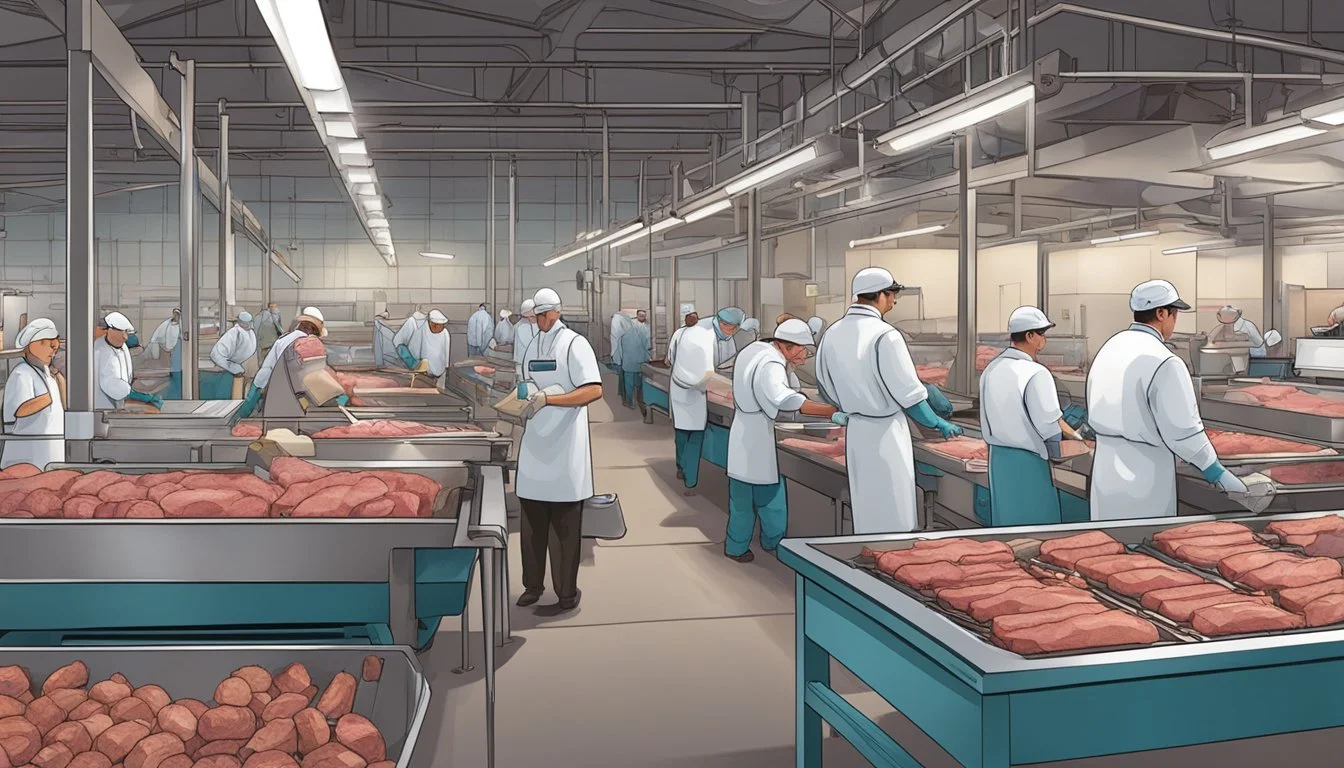

Primary and Secondary Butchering Methods

Primary butchering refers to the initial breaking down of the carcass into large sections called primal cuts. The process starts with evisceration (removal of internal organs) and is followed by skinning in case of beef, sheep, and goats, and defeathering in poultry. The carcass is then sectioned into large pieces, ensuring minimal damage to the meat.

Evisceration: Removal of organs

Skinning: Applied to beef, sheep, and goats

Defeathering: Applied to poultry

Sectioning: Dividing into primal cuts

During secondary butchering, the primal cuts are further divided into retail cuts. This is a more meticulous process as it involves specific knowledge of muscle anatomy and customer preferences. Trimming, deboning, and portioning are common practices, ensuring the preparation of various meat products for sale.

Trimming: Removing excess fat

Deboning: Separating meat from bones

Portioning: Cutting into individual servings

The primary and secondary butchering methods utilize precision and care to maximize product quality and food safety, following stringent sanitary standards.

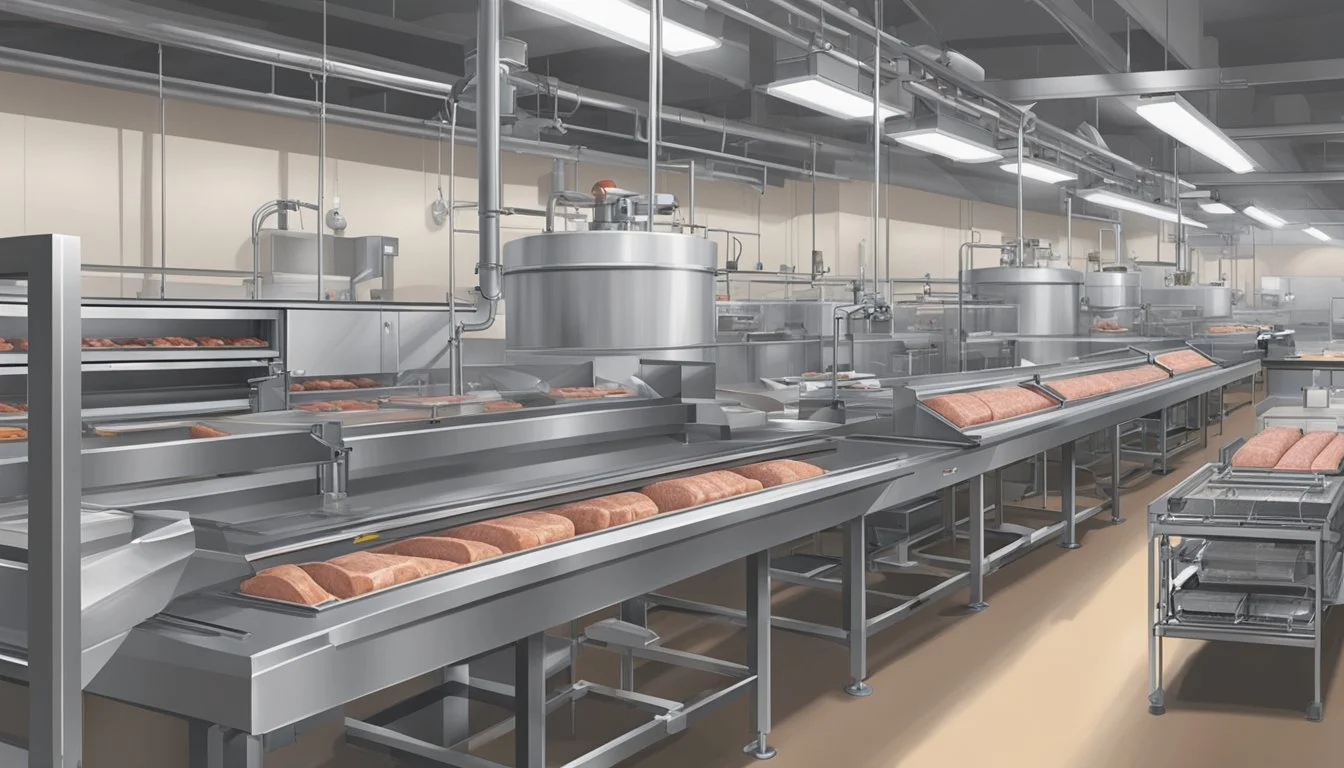

Meat Processing Equipment and Facilities

The establishment and operation of on-farm meat processing facilities require careful planning and consideration of the necessary equipment. Mobile slaughter units and trailers offer a flexible solution for farmers in Delaware to process meat in a timely and efficient manner.

Setting Up an On-Farm Processing Facility

Before farmers in Delaware can establish an on-farm processing facility, they need to assess both their equipment needs and facility layout. Facilities must comply with USDA regulations to ensure food safety and worker health. Key equipment necessary includes:

Stunning devices: to ensure the humane handling of livestock.

Slaughtering tools: such as knives and saws, which must be kept sharp and clean.

Refrigeration units: crucial for meat preservation post-processing.

The facility should also have:

Ample workspace for processing and packaging.

Appropriate waste handling systems to manage by-products.

Mobile Slaughter Units and Trailers

Mobile slaughter units (MSUs) offer a dynamic alternative for meat processing, particularly beneficial for small to mid-size operations.

Features of MSUs include:

Portability: allowing the processing unit to travel to different farm locations.

Complete slaughtering setup: built within a trailer to handle livestock effectively.

MSUs in Delaware must also:

Meet state and local regulatory requirements.

Equip proper waste processing systems to manage offal and other by-products.

Farmers opting for MSUs can:

Minimize animal stress by slaughtering on-site.

Utilize these units to fill gaps during peak processing times.

Health and Safety Standards

In Delaware, on-farm meat processing, butchering, and slaughter must align rigorously with both state and federal health and safety regulations to ensure food safety and workplace hygiene.

Adhering to Food Safety Protocols

The United States Department of Agriculture (USDA) mandates strict food safety protocols to safeguard public health. Facilities must comply with the Federal Meat Inspection Act and the Poultry Products Inspection Act which stipulate:

Inspection Requirements: All animals must be inspected both pre and post-slaughter to ensure they are fit for human consumption.

Record Keeping: Detailed records of the slaughter and processing operations must be maintained to trace any food safety issue back to its source.

Facility Approval: Slaughter and processing facilities must secure USDA approval, which certifies that the setup meets federal guidelines for food safety.

Maintaining Cleanliness and Hygiene

Cleanliness and hygiene are paramount in preventing contamination and ensuring the integrity of meat products. Standards for maintaining hygiene include:

Sanitation Procedures: Regular and documented cleaning schedules that include sterilization of all tools and machinery.

Personal Hygiene: Workers are required to adhere to strict hand-washing protocols and wear appropriate personal protective equipment (PPE).

Pest Control: Effective measures must be implemented to control and document any rodent or insect activity within the facility.

This adherence to cleanliness not only fulfills USDA requirements but also contributes to the holistic safety of the meat processing ecosystem.

Processing Bottlenecks and Solutions

The meat processing industry has encountered significant bottlenecks, particularly highlighted during events such as the COVID-19 pandemic, which have underscored the need for streamlined processing solutions.

Identifying Common Bottlenecks

Bottlenecks in meat processing typically occur when supply exceeds the capabilities of processing facilities, leading to delays and economic losses. Specifically in Delaware, farmers have experienced challenges due to inadequate processing capacity. During the COVID-19 pandemic, this issue was exacerbated as some meat processing plants were compelled to close or reduce their capacity, triggering a ripple effect throughout the supply chain.

Key Bottlenecks Identified:

Limited Processing Capacity: Facilities are overwhelmed by the volume of livestock ready for slaughter.

Closure of Processing Plants: Unplanned shutdowns, such as those during the pandemic, lead to sudden gaps in the supply chain.

Insufficient Butchering Services: A shortage of local butchers contributes to processing delays.

Strategies to Overcome Processing Challenges

Streamlining the processing lifecycle is critical to addressing meat processing bottlenecks. Several solutions have been proposed and implemented to mitigate these challenges:

Mobile Slaughtering Units: These can alleviate the bottleneck by providing on-site processing, reducing the need to transport livestock to distant facilities.

Benefits: Flexibility in location and enhanced capacity for small-scale farmers.

Considerations: High setup costs and significant liabilities related to firearms use.

On-Farm Processing Facilities: Advocated by direct-to-consumer livestock farmers, these facilities can expedite the transition from farm to market.

Benefits: Reduces dependency on large-scale meat processors.

Considerations: Must adhere strictly to hygiene and sanitary regulations.

Adoption of Localized Solutions:

Increased Investment in Local Butcheries: Encouraging the establishment of more local butchering services to prevent supply chain disruptions.

Government Support and Regulations: Implementing supportive policies that promote the resilience of local meat processing infrastructures.

By gearing up localized processing capacities and promoting mobile processing, Delaware can navigate through bottlenecks more effectively, ensuring farmers and consumers alike experience minimal disruptions in the meat supply chain.

Marketplace Considerations for Processed Meat

In Delaware, on-farm meat processing presents unique opportunities and challenges within the meat market, influenced significantly by branding and regulatory compliance.

Branding and Marketing On-Farm Processed Meat

For a farm to secure its position in the meat marketplace, branding is crucial. A strong brand communicates quality and can distinguish farm-processed meat from competitors. Farms should focus on:

Target Market: Identifying consumer segments that value locally processed meat, such as families or culinary professionals.

Unique Selling Proposition (USP): Clearly stating how their meat is superior, whether it's through animal welfare standards, organic feed, or artisanal butchering techniques.

Additionally, marketing strategies are needed to reach potential customers. Farms can employ tools such as social media, farmers' markets, and CSA (Community Supported Agriculture) programs to enhance visibility.

Understanding the Meat Marketplace Dynamics

Navigating the meat marketplace requires an understanding of:

Supply and Demand: Assessing local demand and aligning on-farm production capacity in response.

Competition: Recognizing other local producers and larger commercial entities.

Compliance with regulations is mandatory for on-farm processors, including those set by the USDA and Delaware's state-specific requirements. Processors may choose from two main approaches to compliance:

USDA Inspection: Ensuring the highest level of food safety, allowing for more extensive marketing opportunities.

Exemption Options: This might include on-farm processing under certain conditions, such as processing a limited amount of poultry annually without mandatory USDA inspection.

Farms must understand the regulatory landscape to effectively navigate the market and ensure that their products can be legally sold and distributed. Compliance ensures product safety, consumer confidence, and the longevity of the farm's market presence.

Record Keeping and Traceability

Proper record keeping and implementation of traceability systems are crucial aspects of on-farm meat processing, butchering, and slaughtering in Delaware. These processes ensure compliance with USDA regulations and help maintain high standards of food safety and quality.

Essential Records for Meat Processors

Records are the backbone of any meat processing operation in Delaware, allowing processors to comply with USDA regulations and ensure the integrity of their products. Essential documents include:

Animal Health Records: Information on vaccines, treatments, and inspection results.

Slaughter Records: Details of the slaughter date, animal identification, and inspection stamps.

Processing Records: Capture of butchering steps, storage temperatures, and handling procedures.

Maintaining these records meticulously helps processors trace any issues back to their source, ensuring prompt action if necessary.

Implementing Traceability Systems

Traceability Systems in meat processing involve tracking every stage of the product's journey, from farm to table. Key components for Delaware meat processors to consider:

Identification Tags: Animals are tagged for easy identification, recording details such as the date of birth and farm of origin.

Batch Numbers: Assigning batch numbers to meat cuts helps track the entire processing history.

Software Solutions: Utilize inventory management and traceability software to efficiently store and access all pertinent data.

Implementation of such systems demands an initial investment but is instrumental in safeguarding against health scares and product recalls.

Legal and Liability Issues

When engaging in on-farm meat processing in Delaware, operators must navigate complex legalities and liability risks related to state and federal regulations.

Navigating Liability in Meat Processing

Farm owners in Delaware operating meat processing on their premises face various liability considerations. They must ensure they are operating in compliance with both the Federal Meat Inspection Act (FMIA) and state-specific legislation. Compliance involves maintaining rigorous standards of health and sanitation, waste disposal, and facility construction. Meat processing facilities need to ensure:

Health and Safety Compliance: Strict adherence to health codes and employee safety procedures.

Environmental Regulations: Proper waste management systems that comply with environmental standards.

Animal Welfare: Adherence to humane slaughter guidelines set forth by the USDA.

Failure to meet these requirements can result in severe legal consequences including fines, closure of facilities, and legal actions from consumers or employees.

Understanding Custom Exempt Processing

Delaware recognizes the category of Custom Exempt Processing Facilities, which operate under specific USDA exemptions. This status permits facilities to slaughter and process meat for owners of the livestock exclusively for personal use. It is critical to understand that:

Meat Products: Meat processed at a custom exempt facility cannot be sold or donated to the public.

Labeling Requirements: Meat must be labeled as "Not for Sale" to ensure it is not introduced into commercial food supply chains.

Inspection Requirements: While continuous inspection is not required as in fully regulated facilities, custom exempt operations are subjected to periodic reviews to verify compliance with sanitation and processing standards.

Operators of such facilities bear the liability for ensuring that they do not cross into commercial sales territory unless they have the appropriate processing licenses. They also must manage consumer expectations and understand that liability issues might arise if there is negligence in handling or processing which leads to foodborne illnesses.

Emerging Trends in Meat Processing

In Delaware, advancements in meat processing reflect a broader trend towards innovative technologies and operational efficiencies, aiming to meet both consumer demand and regulatory standards.

Growth of Mobile Slaughtering Operations

Mobile slaughtering units have become a game-changer for Delaware farmers, providing an on-site solution that eliminates the need for transporting livestock. These units ensure that animals are processed in a familiar environment, which can reduce stress for the livestock and potentially improve meat quality. Mobile slaughter operators are trained professionals who travel to farms, equipped with the necessary tools and technology to perform humane slaughtering and initial meat processing. By adhering to stringent safety and quality standards, these operations help local farms diversify their offerings and capitalize on the growing farm-to-table movement.

Innovations in Meat Processing Technology

Delaware's meat processing industry is embracing technological innovations to enhance efficiency and ensure safety. This includes the use of ohmic heating, a method of electrically heating meat to quickly and uniformly cook the product while maintaining its quality. Such technology not only accelerates the meat processing but also offers potential cost savings and a reduced environmental footprint. Innovations in packaging and monitoring systems are further ensuring that meat products are safely processed, stored, and transported, thereby maintaining the confidence of both the consumer and regulatory agencies in the integrity of the meat supply chain.

Future Outlook for Delaware On-Farm Meat Processing

In response to local demand and support from the Delaware Department of Agriculture, the future outlook for on-farm meat processing in Delaware appears poised for growth, addressing both economic and food system needs.

Impact on Local Economy and Food Systems

On-farm meat processing in Delaware holds significant potential to enhance the local economy. By increasing the capacity of slaughterhouses and production facilities, farmers can streamline operations, reduce transportation costs, and provide fresh products directly to consumers. Increased investment, as evidenced by the over $665,000 awarded for innovative projects, is expected to further strengthen this sector. This infusion of funds signifies a commitment to developing a more robust and sustainable food system within the state.

Economic Contributions:

Job creation in rural areas

Revenue for local farmers via diversified income streams

Investment in local infrastructure

Challenges and Opportunities Ahead

While the outlook for Delaware's on-farm meat processing is largely positive, it also faces several challenges. Infrastructure limitations and regulatory hurdles may impede growth, requiring strategic planning and ongoing support to overcome. Opportunities, however, are rife. The push towards localized food systems and shorter supply chains, as encouraged by programs like the Meat and Poultry Processing Expansion Program, opens the door for expansion in the production and processing sectors, potentially leading to a more competitive market and resilient agricultural community.

Operational Challenges:

Meeting regulatory compliance

Upfront costs for setting up or upgrading facilities

Maintaining consistency and quality in production

Strategic Opportunities:

Catering to the niche market for locally-sourced meats

Leveraging grants and governmental support to spur development

Forging partnerships among farmers, processors, and retailers

This focus on enhancing Delaware's on-farm meat processing capabilities indicates a commitment to not just sustaining but expanding the agricultural footprint of the state, thereby benefiting producers, consumers, and the local economy alike.