On-Farm Meat Processing, Butchering and Slaughter in Kansas

Regulations and Best Practices

In Kansas, as in many parts of the United States, the practice of on-farm meat processing is gaining attention as a viable alternative to traditional meat supply chains. The state oversees commercial and custom slaughter facilities, as well as meat and poultry processing plants through the Meat and Poultry Inspection Program. This program ensures that local producers adhere to the necessary regulations to maintain food safety and quality. The interest in these local facilities stems from a desire to close the gap between producer and consumer, offering fresher products and a clearer understanding of the source of the food.

On-farm slaughtering and processing offer a myriad of benefits, such as the ability for farmers to have more control over the quality and handling of their products. It also has the potential to reduce transportation stress for animals and minimize the carbon footprint associated with meat production. Additionally, the state of Kansas provides resources for businesses that specialize in on-farm slaughter. These businesses have to navigate a complex landscape of regulations, including ensuring that a state inspector is present to certify meat for public sale.

There are challenges inherent in establishing an on-farm meat processing facility, including the initial capital investment and navigating public opinion as well as adherence to strict regulations. Nevertheless, Kansas producers are increasingly exploring on-farm processing to increase their financial resilience and to meet a market demand for locally sourced meats. As consumer interest in the origins and treatment of food continues to grow, on-farm processing in Kansas represents a commitment to transparency, quality, and sustainability in agriculture.

Overview of On-Farm Meat Processing in Kansas

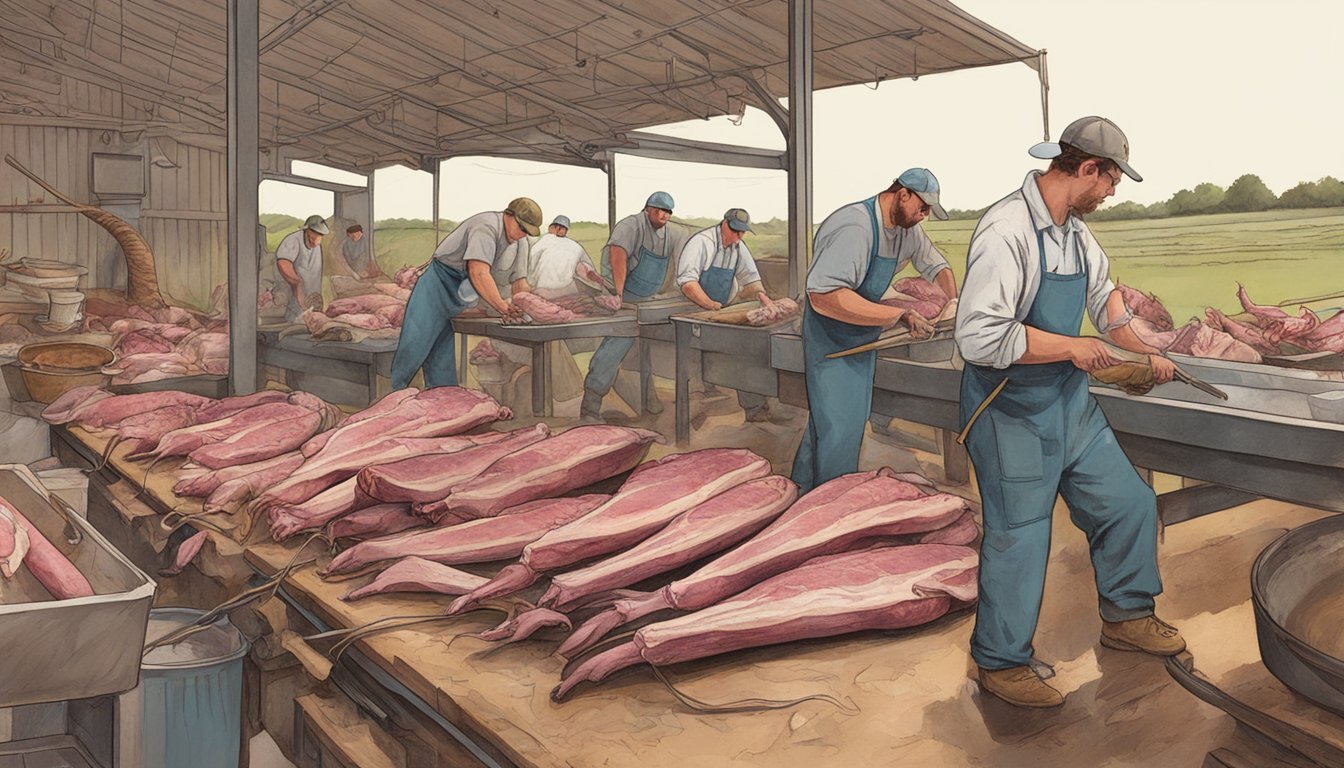

In Kansas, on-farm meat processing comprises various steps, including slaughter, butchering, and packaging. Local farmers have adopted this approach to meet the consumer demand for locally produced meats. Kansas Department of Agriculture regulates these practices, ensuring commercial and custom slaughter facilities, along with meat and poultry processing facilities, comply with state standards.

The farmers are part of a larger trend that emphasizes local food systems. By processing meat on their farms, they offer consumers a direct connection to their food sources. As a component of this, Kansas State University has played a pivotal role by initiating efforts to expand the capacity of meat processors in the state. This initiative supports farmers by providing expertise and resources to help them grow their on-farm processing operations.

Typical on-farm processing includes:

Slaughtering animals humanely

Butchering carcasses into cuts

Packaging meat for sale or storage

Farmers benefit from this vertical integration by retaining greater control over their products, from raising livestock to selling meat directly to consumers or local businesses. Challenges such as the need for investment in processing infrastructure and adherence to regulatory oversight are part of the business. However, the support from research institutions and the state's interest in expanding this sector portray a promising future for on-farm meat processing in Kansas.

Regulatory Landscape for Slaughter and Processing

The complex regulatory environment surrounding on-farm slaughter and processing in Kansas is dictated by both state and federal regulations designed to ensure food safety and proper handling of meat.

State and Federal Regulations

Both state and federal laws impact the way meat is slaughtered and processed on farms in Kansas. State regulations are overseen by the Kansas Department of Agriculture (KDA), which coordinates with the federal Food Safety and Inspection Service (FSIS) to ensure compliance. The KDA's role is crucial as it provides guidance and oversight to farms operating within state lines. On the federal level, FSIS under the United States Department of Agriculture (USDA) is responsible for ensuring that meat products are safe, wholesome, and correctly labeled and packaged.

State-Inspected Meat: Kansas has its own state inspection program which aligns with federal standards. Meat products from state-inspected facilities can be sold within the state.

Federal Oversight: For meat to be sold across state lines, it must be processed in a federally inspected facility, adhering to FSIS regulations.

Regulatory Cooperation between state and federal agencies ensures compliance with both sets of regulations. This cooperative framework is designed to maintain a robust system for food safety and public health protection.

Food Safety and Inspection Requirements

Food safety remains the cornerstone of slaughter and processing regulations. Food Safety protocols are enforced to mitigate the risks of foodborne illnesses and contamination.

Inspection: All slaughter and processing facilities must have their operations inspected regularly. For federal inspection, FSIS provides continuous on-site inspection during slaughtering and intermittent inspection during processing.

Processing: Facilities must maintain proper sanitation, handle animals humanely, and implement Hazard Analysis Critical Control Point (HACCP) systems. HACCP is a management system in which food safety is addressed through the analysis and control of biological, chemical, and physical hazards.

Through rigorous enforcement of health and sanitation requirements, both state and federal agencies work to ensure that the processing of meat is done safely and to the highest quality standards, protecting the end consumer.

Infrastructure for Meat Processing

In Kansas, advancements in on-farm meat processing involve the establishment of fixed slaughterhouse facilities and the utilization of mobile slaughtering units. These components are transforming how livestock are processed, optimizing meat quality, and benefiting local farmers by providing more control over their meat production processes.

Fixed On-Farm Slaughterhouse Facilities

Fixed on-farm slaughterhouse facilities in Kansas are permanent structures designed to handle the slaughter and processing of livestock, including cattle, hogs, goats, and sheep. These facilities are equipped with the necessary infrastructure to ensure the meat produced meets safety and quality standards. The presence of on-site slaughterhouses allows farmers to streamline the meat production process, from rearing to packaging, resulting in shorter supply chains and potentially reducing stress for the animals, which can impact meat quality.

Key Features of Fixed Slaughterhouse Facilities:

Permanent infrastructure with designated areas for slaughtering, butchering, and meat processing.

Inclusion of refrigeration and storage units to ensure meat preservation.

Compliance with regulatory standards for sanitation and animal welfare.

Mobile Slaughtering Units

Mobile slaughtering units (MSUs), or mobile abattoirs, provide a versatile and cost-effective option for Kansas farmers, especially those with smaller herds or those located in remote areas. These MSUs are essentially customized trailers equipped with all the tools necessary for on-site slaughter and processing. A significant advantage of mobile slaughter is the reduction in the need for livestock transport, which can decrease the stress on the animals, thus potentially enhancing meat quality.

Advantages of Mobile Slaughtering:

Flexibility to service multiple farms, reducing the need for extensive travel of live animals.

Can be a practical solution for small-scale farmers or those seeking specialty processing.

Enables processing in accordance with regulatory standards, directly on the farm.

By employing both fixed and mobile infrastructures for meat processing, Kansas farmers are able to cater to diverse market needs, ensure animal welfare, and maintain high standards of meat quality.

Animal Handling and Welfare

In Kansas, the approach to animal handling and welfare is a critical aspect of on-farm meat processing. Practices are implemented to reduce stress during slaughter and support the lifestyle of pasture-raised and grass-fed livestock, ensuring the humane treatment of cattle and sheep.

Stress Management During Slaughter

Proper handling of livestock during the slaughter process is vital to minimize stress, which can influence meat quality. Ranchers in Kansas employ various techniques to ensure a calm environment for the animals leading up to the slaughter.

Pre-Slaughter Handling: Animals are kept in familiar surroundings with minimal disruptions. Sudden movements and loud noises are avoided to prevent distress.

Transportation to Slaughter: When transport is necessary, it's done over short distances with careful handling to mitigate stress.

Humane Slaughter Practices: Employing quick and efficient methods such as captive bolt stunning, which renders the animal unconscious instantly, ensures a painless and stress-free kill.

Pasture-Raised and Grass-Fed Livestock Practices

Animal welfare extends beyond the slaughter process, with pasture-raised and grass-fed practices being integral to livestock rearing in Kansas.

Pasture Access: Cattle and sheep are given access to pastures, allowing them to graze naturally, promoting physical health and psychological well-being.

Grass-Fed Diets: Animals are provided a diet of grass, which is their natural food source, supporting better digestibility and overall health.

Physical Health Monitoring: Regular health checks by ranchers ensure early detection and treatment of any potential issues, reducing the need for interventions that may cause stress.

In managing the welfare of animals, Kansas ranchers demonstrate a commitment to ethical livestock practices, aligning with both consumer demand for humane treatment and the needs of the animals under their care.

Processing Bottlenecks and Solutions

In Kansas, the timely processing of meat is critical to farmers, consumers, and the overall health of the agricultural industry. This section specifically addresses the challenges and solutions related to this process.

Identifying Processing Bottlenecks

The primary bottlenecks in meat processing stem from limited access to slaughterhouses and skilled labor. Covid-19 exacerbated these issues, reducing processing capacity at a time when demand remained constant or increased. Moreover, lack of genetic selection and inadequacies in grazing practices can affect livestock quality and processing efficiency. Soil health also plays a crucial role, as it indirectly impacts the volume and quality of livestock suitable for processing.

Limited processing facilities

Inadequate skilled workforce

Impact of Covid-19 on operations

Suboptimal livestock quality

Impaired soil health

Innovative Practices to Alleviate Bottlenecks

Kansas has seen innovative practices to address the meat processing bottleneck. Mobile slaughtering units and on-farm facilities are emerging solutions that mitigate the reliance on centralized slaughterhouses.

Mobile Slaughtering Units: These provide a flexible approach to processing, enabling animals to be processed on-site, reducing transportation stress on livestock, and providing fresher products.

On-farm Processing Facilities: Encouraging on-farm slaughter can alleviate pressure on traditional processing plants and allow farmers to directly control the end-to-end quality of their products.

Both approaches support better soil health by enabling more holistic farm management practices, including rotational grazing and avoidance of overstocking. The state can further alleviate bottlenecks by investing in vocational training programs to address the skilled labor shortage, thus ensuring a resilient future for Kansas's meat processing industry.

Meat Quality and Butchering Techniques

Meat quality and butchering techniques are paramount in determining the final product that reaches consumers. In Kansas, where beef and pork are substantial contributors to the agricultural economy, maintaining high standards for meat production and processing skills is essential.

Ensuring High-Quality Meat Production

The foundation of high-quality meat hinges on multiple factors starting with the on-farm practices and extending through to the moment of slaughter. Specifically for beef and pork, the age of the animal, its diet, and the living conditions are crucial for determining its carcass quality. A balance of proteins, fibers, and fats in the feed, along with ample space for movement, contributes to both the texture and flavor profile of the meat. Kansas farmers are vigilant with their livestock, ensuring animals are raised in stress-free environments; stress can lead to toughening of the meat and adversely affect the pH levels in the carcass, thereby impacting the quality.

An optimal slaughtering process also plays a significant role. The transition of the carcass from the farm to the rail must be done efficiently and humanely to prevent any quality deterioration. State-inspected mobile slaughtering units are becoming increasingly relevant in Kansas for small-scale farmers, providing a method to reduce stress on the animals by minimizing transportation.

Butchering and Meat Cutting Skills

Butchering requires precision and expertise, particularly when transforming a carcass into market-ready cuts. Kansas butchers are skilled craftsmen, adept at using their knowledge of animal anatomy to maximize yield and ensure the highest meat quality. Beef carcasses, typically larger and more complex, demand different techniques compared to pork, which may require a varied approach due to differing fat content and carcass structure.

When cutting meat, butchers must navigate through different muscle groups, connective tissues, and fat deposits. They do this with a keen understanding of how each cut impacts texture and flavor. This expertise ensures that Kansas meat is not only safe and hygienic but also tailored to consumer preferences in terms of cut size, tenderness, and culinary application. Butchers are further responsible for ensuring that their techniques adhere to local regulations and that the meat is processed in a manner that maintains its integrity from farm to table.

Economic and Business Considerations

The economic viability and management of business risks are central to the operation of on-farm meat processing facilities. These aspects dictate the operational success and sustainability of such ventures in Kansas.

Costs and Revenue for On-Farm Processing

The undertaking of on-farm meat processing requires substantial financial investment. Livestock farmers must consider the costs of equipment, facility upgrades, and staff training. Initial capital expenditures might include purchasing processing equipment like slaughter tables, refrigeration units, and cutting tools, and potentially constructing a dedicated processing space. Operating expenses comprise utilities, maintenance, and labor, as well as ongoing costs such as purchasing and maintaining tools and supplies.

Revenue streams for on-farm processed meat can be diversified. Sales might include direct-to-consumer transactions, farmers' markets, or supplying local businesses. Pricing should accommodate both the cost of production and the market's willingness to pay for locally processed meats.

Typical Investments:

Equipment: $20,000 - $300,000

Facilities: $100,000 - $1,000,000+

Training: $1,000 - $5,000

Operating Costs (Annually):

Utilities: $2,000 - $10,000

Labor: Varies widely depending on facility size and throughput

Revenue Sources:

Direct sales

Local markets

Wholesale to businesses

Liability and Risk Management

On-farm meat processing carries inherent risks. Farmers must adhere to federal and state regulations on meat processing and food safety, and failure to do so can lead to liability concerns. Appropriate insurance is not just recommended; it's a critical component of risk management. Insurance can cover a breadth of potential issues, from employee injury to product liability.

Liability Considerations:

Product recalls

Customer illness

Regulatory non-compliance

Insurance Types:

General Liability Insurance: Protects against general risks associated with the facility and operations.

Product Liability Insurance: Covers the risks related to the consumption and use of the meats processed on-farm.

Worker's Compensation: Mandatory for employing companies, covering employee workplace injuries.

On-farm processors should establish clear protocols for all processing stages, insure against potential risks, and keep meticulous records. By doing so, they manage both the economic and liability aspects of their business effectively, ensuring its longevity and compliance with regulations.

Environmental Impact and Sustainability

In Kansas, on-farm meat processing implicates a series of environmental considerations. These encompass vigilance regarding waste management and the maintenance of soil health. Practices promoting sustainability now inform modern butchering and meat processing operations.

Waste Management and Sewage Treatment

Waste Management: The disposal and treatment of waste products from meat processing are crucial. In Kansas, adequate waste management safeguards local ecosystems. Livestock operations generate a mixture of organic waste and wastewater, which need meticulous handling to prevent contamination of soil and water resources.

Solid Waste: includes unused tissue and bone. It is often transformed into byproducts through rendering or composting.

Liquid Waste: primarily effluent, must be treated before release into the environment.

Sewage Treatment: On-farm slaughter facilities must align with stringent sewage treatment protocols to mitigate adverse environmental impacts.

Treatment Ponds: Some farms use lagoons for biological waste treatment.

Advanced Systems: Involving filtration and chemical processes ensure that when water leaves the farm, it meets environmental safety standards.

Such treatment systems not only protect water quality but also contribute to soil health, as properly treated waste can be used as fertilizer, enhancing the nutrient content without resorting to chemical inputs. This circular approach to waste underscores the sustainability efforts in Kansas' meat processing industry, maintaining the delicate balance between agricultural productivity and environmental stewardship.

Market Dynamics and Consumer Demand

In Kansas, on-farm meat processing confronts a transforming landscape shaped by evolving consumer demand and the growing prominence of local and niche meat markets. This section delves into the key aspects of market dynamics and consumer preferences that influence the state's meat industry.

Local and Niche Meat Markets

Local meat markets in Kansas have experienced a surge in demand as consumers increasingly seek transparency and shorter supply chains. The direct selling of meat from ranch or farm to consumer has garnered attention, with an emphasis on the source and conditions under which livestock is raised and processed. The local marketplace differentiates itself through these aspects, creating a burgeoning sector within Kansas' meat industry.

Transparency: Kansas consumers are asking for clear information about where their meat comes from and how it is processed.

Supply Chain Dynamics: There is a trend towards reducing the distance food travels, which has led to a rise in on-farm slaughtering and butchering to serve the local populace.

Consumer Preferences for Pasture-Raised Meat

Consumer demand in Kansas shows a distinct preference for pasture-raised meat, which is perceived as a healthier and more ethically produced option. Pasture-raised livestock practices, often associated with small-scale farms, resonate with consumers' environmental consciousness and animal welfare concerns.

Health Consciousness: Consumers opt for pasture-raised meat due to beliefs about its nutritional benefits and overall quality.

Ethical Choices: The welfare of animals and the desire to support environmentally sustainable practices are influencing factors for consumers when purchasing meat.

The meat market in Kansas is adapting, with consumer preferences leaning towards locally sourced and pasture-raised meat. This shift presents opportunities for local producers to develop niche markets that satisfy specific consumer demands.

Emerging Trends in On-Farm Meat Processing

Mobile Slaughtering Units: Kansas farmers are adopting mobile slaughtering as a versatile solution to processing bottlenecks. With the capacity to process 25-30 beef and 30-40 hogs per week, these units assist small-scale farmers by providing on-farm slaughter services for both custom and state-inspected meat.

Meat Science Integration: Recent trends show a rise in implementing meat science advances on the farm. These practices are influencing carcass and meat quality, aiming to reduce inconsistencies. Farmers and processors are focusing on factors from genetic selection to feed that directly impact meat quality.

Adjustments Post-COVID: The global pandemic affected the traditional meat supply chain, prompting Kansas farmers to shift towards on-farm processing to meet demand and mitigate socio-economic impacts. Adapting to changes brought on by COVID-19, farmers are incorporating improved sanitary practices and social distancing measures during animal processing.

Technological Innovations: Efficiency increases as farmers integrate technology into traditional butchering practices. They are pursuing innovations that differentiate their products and streamline operations, making local markets more accessible and responsive to consumer trends.

In summary, Kansas is experiencing a shift in meat processing practices, propelled by mobile slaughtering, a scientific approach to meat production, the adjustments required by the pandemic, and technological progress in the field. These trends are redefining on-farm meat processing, boosting resilience and local meat provision.

Additional Resources and Further Reading

For those interested in meat processing, butchering, and slaughter in Kansas, meat science and regulatory compliance are crucial areas to understand. A number of resources offer guidance and support on these topics.

Meat Science and Processing Information:

Agriculture Extensions:

Kansas State University Meat Science: Provides research and educational resources on meat processing techniques.

Niche Meat Processor Assistance Network (NMPAN): Offers studies and reports on local meat processing.

Regulations and Compliance:

Food Safety & Inspection Service (FSIS): Stay updated with processing regulations on the U.S. Department of Agriculture (USDA) website.

State-Specific Regulations: Consult the Kansas Department of Agriculture for local regulations and compliance standards.

Educational Material and Fact Sheets:

Extension Fact Sheets: They often provide essential information on legalities and best practices for on-farm processing. Look for fact sheets similar to those offered by Ohio State University Extension on their website which may be adapted for Kansas.

Funding and Grant Information:

USDA Rural Development: Announcements from USDA regarding funding availability for meat and poultry processors can be found on the USDA website.

Resource Type Description Link/Location Meat Science KSU resources and expertise KSU Agriculture Department Regulatory Guidance FSIS and USDA guidelines USDA Website Educational Materials Fact sheets and guidelines State Extension Websites (e.g., KSU) Funding Opportunities Grants for processors USDA Rural Development Announcements

For a deeper insight into meat and poultry processing, individuals should stay abreast of literature and updates from these sources that are grounded in industry and academic expertise.