On-Farm Meat Processing, Butchering and Slaughter in Louisiana

A Guide to Local Practices

On-farm meat processing is an integral component of Louisiana's agricultural landscape, where tradition and modernity converge in the realm of animal husbandry and butchery. In Louisiana, farmers and producers are embracing on-farm meat processing to gain more control over their products from pasture to plate. This approach not only strengthens the local food system but also ensures that the traditions of butchering and slaughter are maintained within the community, all the while complying with both state and federal regulations.

The year 2022 saw a growing interest in local meat processing as Louisiana producers sought ways to bypass supply chain disruptions and market volatility. By establishing on-farm slaughter and butchering facilities, these agricultural entrepreneurs aimed to deliver fresher products and create a more resilient food economy. The process of transforming livestock into market-ready meat on the farm presents a set of challenges, including significant capital investment, adherence to stringent regulatory standards, and managing public perception.

Louisiana's move towards on-farm meat processing also highlights the dual benefits of fostering economic growth while retaining the authenticity of local cuisine. The state has a rich culinary heritage that values the quality and sourcing of ingredients, and on-farm meat processing guarantees that the meats are fresh, with a known provenance. Producers engaging in these practices underline their commitment to sustainability while creating value-added products that resonate with consumer preferences for responsibly-raised meats.

Overview of On-Farm Meat Processing

In Louisiana, on-farm meat processing is a pivotal aspect of the agricultural sector, providing farmers with a means to directly influence the meat supply chain. This processing refers not only to the butchering and slaughtering of livestock but also to the various aspects of meat preparation that happen at the local level.

Importance in Louisiana

On-farm meat processing in Louisiana represents a vital component of the agricultural market. It allows farmers to have a closer connection to the final product, thereby granting them greater control over quality and sales. Local meat processing facilities help to mitigate the meat processing bottleneck that can occur due to centralized processing systems. By having operations on the farm, farmers can reduce transportation costs and stress on the livestock, ultimately leading to fresher and potentially higher-quality meats for consumers.

Historical Context and Evolution

Historically, Louisiana's farming community handled meat processing at the local or on-farm level out of necessity. It used to be a tradition informed by self-reliance and community trade. Over time, the evolution of this practice has been influenced by regulatory changes and advancements in technology. Farmers have adapted to balance adherence to regulations while striving to maintain the viability of their operations in the face of fluctuating agricultural markets. Presently, entities like the McNeese State University's CAMPP Meat Production and Processing facility offer education and resources that reinforce on-farm meat processing practices, highlighting not only historical continuity but also innovation within the field.

Regulatory Framework

The regulatory framework governing on-farm meat processing in Louisiana involves a complex interplay between federal and state regulations ensuring food safety and compliance.

State vs Federal Inspection

The main distinction between state and federal inspection lies in the reach of meat products. Federal inspection is mandatory for meat to be sold across state lines and is overseen by the USDA's Food Safety and Inspection Service (FSIS). State inspection, on the other hand, is managed by state authorities for meat products sold within Louisiana. Despite the level of oversight, both pathways adhere to stringent food safety regulations to ensure public health.

Licensing and Compliance

In Louisiana, processors must obtain proper licensing to operate legally. They must demonstrate compliance with both state and federal regulations, which includes facility sanitation, proper handling, and processing of meat. Regular inspections ensure ongoing adherence to these requirements. Failure to maintain compliance can result in fines or the revocation of the license to operate.

USDA Regulations

All meat processing facilities under USDA inspection must follow the guidelines established by the Federal Meat Inspection Act (FMIA). These rigorous regulations are in place to certify that all meat is safe, wholesome, and properly labeled. The FSIS is the federal body responsible for the inspection service that enforces these standards.

State-Inspected Processing

Louisiana’s Federal/State Meat Program ensures the safety and wholesomeness of meat processed at state-inspected facilities. State regulations mirror federal standards and are enforced by Meat Inspection personnel. Facilities that qualify for state inspection are subject to many of the same requirements as their federally inspected counterparts but are limited to selling their products within the state.

Processing Techniques

The processing of meat in Louisiana encompasses a spectrum of techniques ensuring humane handling and high-quality butchering practices. These well-established methods aim to minimize stress for the animals and provide safe, wholesome products for consumers.

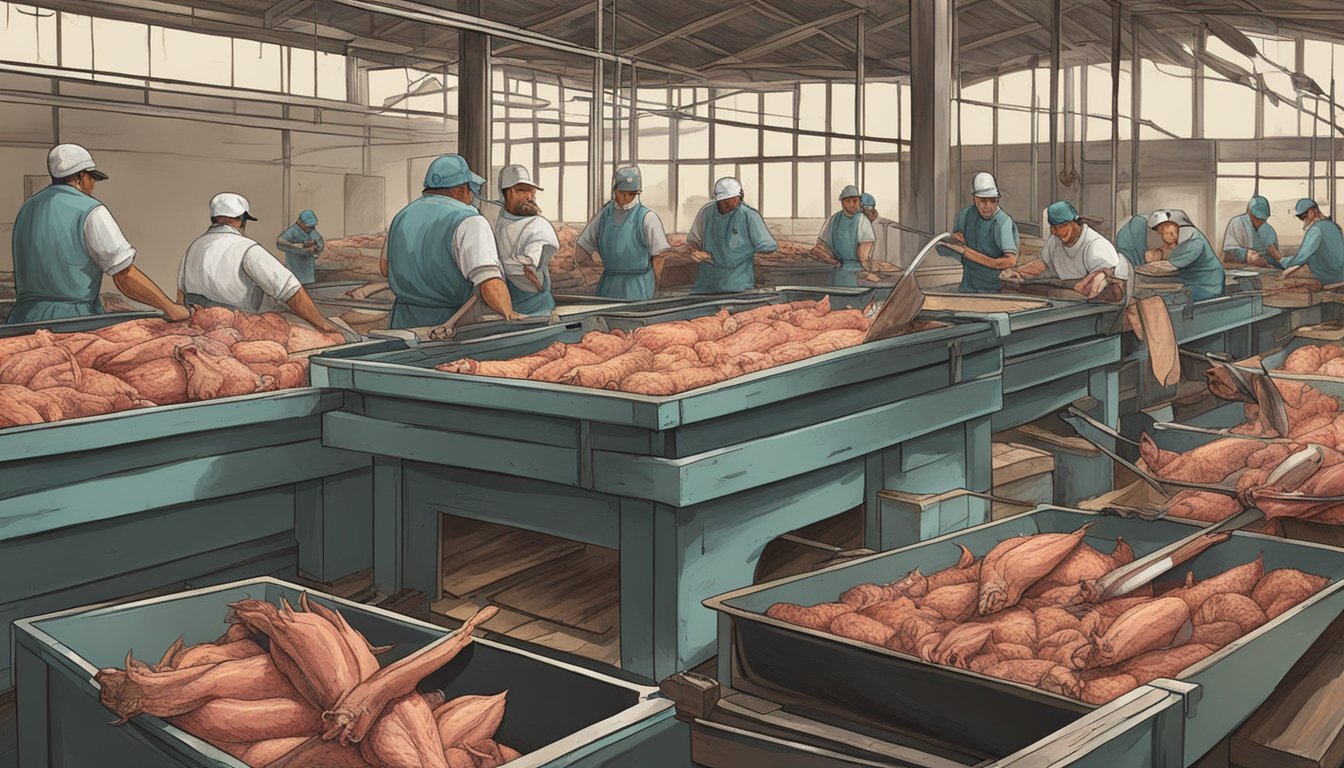

Butchering Practices

In Louisiana, butchering is typically done in facilities that adhere to strict regulations to maintain hygiene and product quality. Artisan butchers and larger processing plants engage in methods such as dehairing, evisceration, and precise cutting to transform livestock into retail cuts. They start by cleaning the carcass thoroughly before dehairing, commonly using scalding or torching techniques. The next step is evisceration, which involves a clean, straight incision to remove the internal organs, often done with specialized equipment to prevent contamination.

Key steps in the butchering process:

Inspection: Pre- and post-mortem inspections for signs of disease or contamination.

Skinning and Dehairing: Removal of the hide or hair from the carcass.

Evisceration: Careful removal of internal organs to prevent contamination of the meat.

Division: Separation of the carcass into primal cuts for further processing or sale.

Humane Handling and Slaughter

Humane handling and slaughter are integral parts of the meat processing protocol. Stress in animals not only raises ethical concerns but also can negatively affect meat quality. Handlers are trained to use techniques that reduce stress and fear, leading to a more humane slaughter process. Facilities are designed to provide a calm environment, utilizing non-slip surfaces and curved chutes to facilitate animal movement without resistance.

Considerations for humane handling:

Training: Workers are trained in animal behavior and low-stress handling techniques.

Facility Design: Using features that promote calm, such as curved chutes and non-slip floors.

Stunning Methods: Employing methods such as captive bolt stunning to render animals unconscious quickly and humanely before slaughter.

All processes comply with the regulations set forth by state and federal agencies to ensure the animals' welfare and meat safety, reflecting the commitment to high standards within the industry.

Facility and Equipment Considerations

In Louisiana, on-farm meat processing facilities must adhere to a set of infrastructure and equipment criteria to ensure compliance with regulations. Key considerations include the setup of stationary facilities, the implementation of mobile slaughter units, and the management of resultant waste.

Infrastructure Requirements

Proper infrastructure is the backbone of any on-farm slaughter operation. At minimum, facilities should include:

A sturdy, weatherproof building to house processing activities.

An adequate water supply and sewage treatment system to manage wastewater.

A reliable electricity source, often provided by a generator, to power equipment consistently.

Cooling and refrigeration systems are essential for meat preservation, while stainless steel tables and non-porous surfaces are necessary for maintaining hygiene during processing.

Mobile Slaughtering Units

Mobile slaughter units (MSUs) offer a versatile solution for farmers. These self-contained units must be:

Designed for ease of transport and able to navigate to various farm locations.

Equipped with processing equipment similar to stationary facilities, including tools for slaughtering, cutting, and packing.

Fitted with waste storage solutions to temporarily hold by-products until they can be properly disposed of.

Waste Disposal and Management

Effective waste disposal and management are critical to avoiding environmental contamination. Components include:

Wastewater treatment plans that prevent run-off and adhere to state environmental regulations.

Solid waste (e.g., offal) must be disposed of or repurposed according to Louisiana's agricultural waste standards.

Integration with local sewage systems or on-site treatment facilities to manage effluent from the slaughtering process.

Regular monitoring and maintenance help ensure that waste systems operate within legal and ethical boundaries.

Operational Challenges

On-farm meat processing in Louisiana faces several hurdles, particularly in areas such as managing seasonal demand swings, navigating logistical constraints, and ensuring adequate labor and training for high-quality operations.

Managing Seasonal Demand

In Louisiana, meat processors often experience fluctuating demand throughout the year. Peak seasons, such as those immediately prior to major holidays, can strain the capacities of processing plants, compelling them to scale operations up or down rapidly. This can be especially challenging for smaller, on-farm slaughterhouses that have limited space and resources to adjust to these fluctuations.

For example, during hunting seasons or specific agricultural periods, the demand for processing can significantly exceed the usual rate, leading to backlogs if not managed properly.

Logistical Constraints

Transporting livestock to slaughterhouses and meat products to markets involves an intricate logistics network that can be particularly complex in rural Louisiana. Local infrastructure may not always be conducive to efficient transportation, and meat processors must ensure they have reliable access to cold storage and distribution channels. During disruptions such as those experienced during COVID-19, maintaining a steady supply chain becomes even more challenging.

Accessibility to hot water and proper waste management systems is also paramount in maintaining operational efficiency and complying with health regulations, but this can pose a constraint for smaller or remote facilities.

Labor and Training

The workforce within on-farm slaughter facilities must be highly skilled in a range of tasks from slaughtering to butchery. However, securing a steady supply of trained workers is not always straightforward. The labor-intensive nature of meat processing demands a combination of physical aptitude and expert knowledge, which necessitates comprehensive training programs.

The advent of COVID-19 has further complicated this, not only by affecting the available labor pool but also by necessitating additional training in health and safety protocols. To sustain high standards and regulatory compliance, ongoing education and development are essential for every individual involved in the meat processing lifecycle.

Animal Welfare and Stress Management

When processing meat on-farm in Louisiana, humane handling of livestock is paramount for both animal welfare and meat quality. Stress management throughout the slaughtering process is a critical concern, as stress can lead to poor carcass quality, impacting both the texture and flavor of the meat.

Humane Handling Practices:

Producers ensure livestock are treated with care to minimize stress. This includes proper transport, housing, and handling procedures before and during slaughter.

Transportation: Animals are moved with care, avoiding overcrowding and excessive handling.

Housing: Adequate space, ventilation, and access to water are provided.

Handling: Workers are trained in low-stress techniques, taking into account the animal's natural behavior.

Stress Reduction During Slaughter:

To manage stress, the animals are kept calm by employing various methods which may include:

Environment: A quiet, familiar environment is maintained to keep stress levels in check.

Slaughter Techniques: Quick and efficient methods are utilized to minimize suffering and stress.

Impact on Carcass Quality:

Stress manifests in the carcass, affecting both its appearance and its biochemical properties. Elevated stress levels can lead to conditions such as:

PSE (Pale, Soft, Exudative) Meat: Pale in color, soft texture, and prone to moisture loss.

DFD (Dark, Firm, Dry) Meat: Darker color, tougher texture, and less palatable.

By prioritizing animal welfare and stress management, Louisiana’s on-farm meat processors aim to produce meat of higher quality, ensuring both ethical standards and consumer satisfaction are maintained.

Market Dynamics and Consumer Demand

Consumer trends in Louisiana reflect a growing interest in pasture-raised meat and localized marketing strategies to meet demand.

Trends in Pasture-Raised Meat

The demand for pasture-raised meat in Louisiana is driven by consumers' desire for products that are perceived as healthier, environmentally friendly, and supportive of animal welfare. Pasture-raised meat signifies that animals were raised with access to outdoor spaces, which aligns with the values of an increasing segment of the market seeking transparency in meat production.

Local farms are responding by raising cattle, pigs, poultry, and other livestock in pasture-based systems. These systems not only cater to consumer preferences but also often allow for diversified farm income streams. The interest in pasture-raised meat is part of a broader shift toward sustainable agriculture practices in the region.

Local Meat Marketing Strategies

Marketing strategies for local meat in Louisiana are evolving to capitalize on the burgeoning demand for products that emphasize local provenance and quality. Farms and butcher shops are utilizing a mix of direct-to-consumer sales, farmers' markets, and partnerships with local restaurants to reach their target audiences.

Farmers' Markets: A key sales avenue where farmers can directly engage with consumers, offering insights into production practices.

Community Supported Agriculture (CSA): Many farms are creating subscription services that provide a regular meat supply to local consumers.

Online Platforms: Digital storefronts and social media marketing are important tools for local meat producers to share their story and product offerings.

Efforts to streamline these marketing strategies involve a deep understanding of local consumer behavior and leveraging the narrative of upscale, ethical, and local consumption.

Challenges and Opportunities for Small-Scale Producers

Small-scale meat producers in Louisiana are confronted with a unique set of challenges and opportunities, especially when it comes to on-farm processing. They strive to meet consumer demand and maintain high standards of quality, all while navigating stringent regulations and logistical difficulties.

Navigating Meat Processing Bottlenecks

For small-scale producers in Louisiana, one of the most significant hurdles is the meat processing bottleneck. This occurs when the limited number of USDA-certified facilities cannot handle the volume of animals ready for processing, leading to delays that can affect the freshness and profitability of the meat. Delays in processing can result in significant financial losses for farmers, who must then either keep their animals longer than planned, which increases feeding costs, or sell them at lower prices due to oversupply.

Potential solutions include:

Developing on-farm processing facilities to overcome reliance on external processors.

Lobbying for state policy changes that support mobile or smaller processing units with less stringent requirements for small volumes.

Building Cooperative Models

The concept of cooperative models presents a strategic opportunity for small-scale producers to overcome the challenges of meat processing. By pooling resources, they can gain collective bargaining power and invest in shared processing facilities. This cooperative approach can lead to more consistent and cost-effective processing options, better market access, and higher revenue streams for all members involved.

Advantages of cooperatives include:

Shared investment in equipment and facilities reduces individual costs.

Increased negotiating power with suppliers and retailers.

Ability to share best practices and knowledge amongst members.

By taking advantage of cooperative models and addressing meat processing bottlenecks, small-scale producers in Louisiana can enhance their operations and secure their presence in the market.

Community and Environmental Impact

On-farm meat processing brings significant community and environmental considerations into focus. The implications for neighbor relations and sustainability practices in Louisiana are complex, reflecting a balance between agricultural demands and ecological welfare.

Neighbor Relations

Neighbors to farms with on-farm meat processing operations may experience a range of impacts. Noise, odor, and increased traffic are primary concerns. To mitigate tensions, farm owners often engage in proactive communication, setting expectations and working collaboratively to establish operating hours that respect local norms.

Noise: Operations, especially during peak processing times, can elevate noise levels. Sound buffers or designated processing times can minimize disruption.

Odor: Effective waste management systems are essential to reduce olfactory impacts. Incorporating strategies such as covered manure storage and timely waste removal can help maintain neighborly relations.

Sustainability Practices

Sustainability is a key facet of on-farm meat processing in Louisiana. Farms strive to minimize their environmental footprint through various practices:

Waste Management: Properly handling by-products and waste to prevent waterway contamination is crucial. Aspects like manure processing and wastewater treatment reduce environmental harm.

Feed Sourcing: Farms often source feed locally, cutting down on transportation emissions and supporting local agriculture.

Climate Change Mitigation: Many farms contribute to climate change mitigation by adopting practices such as renewable energy use, carbon footprint reduction, and resource conservation.

Farmers implement these practices to foster long-term, sustainable production while aiming to coexist peacefully within their communities and steward the surrounding environment.

Industry Case Studies

This section explores specific instances of on-farm meat processing, with a focus on successful operations in Louisiana and how they compare to practices in Wisconsin.

Louisiana Success Stories

Bayou Butchers in Louisiana have become a paradigm of on-farm meat processing efficiency. They provide comprehensive services from slaughter to packaging, which caters to the needs of local ranchers. By focusing on cattle butchering, they help maintain a robust local beef industry. Their model emphasizes:

Direct-to-consumer sales

Commitment to humane handling

Use of traditional butchering techniques

Cajun Cutters is another success story that has leveraged community support and high-quality cattle processing to establish a strong brand presence. They've achieved this through:

Rigorous quality control standards

Strong relationships with local ranchers

Embracing modern refrigeration and packaging methods

Comparative Analysis: Wisconsin

When comparing Louisiana's on-farm meat processing to practices in Wisconsin, certain differences and similarities become evident. In Wisconsin, the climate presents unique challenges and opportunities for meat processors:

Colder temperatures can aid in meat preservation and storage.

Diverse livestock population, including dairy and beef cattle, contributes to a varied meat processing industry.

Wisconsin's meat processing facilities, such as Prairie Ranch Processors, share similarities with Louisiana's butchers:

They also work closely with local farmers.

Uphold strict safety and quality standards, reflecting the USA's broader regulations.

However, they often face more stringent winter operation conditions, which affects their scheduling and processing logistics. Wisconsin has a legacy of dairy farming that influences its meat processing sector, adding a layer of complexity to its industry with specialized cheese and dairy beef markets.

Legal Considerations and Liability

When engaging in on-farm meat processing, butchering, and slaughter in Louisiana, farmers and operators must navigate a series of legal considerations to ensure compliance and limit liability. The primary legal framework governing these activities includes federal and state statutes, among which the Federal Meat Inspection Act and state-specific regulations are critical.

Custom Exempt Plants: These facilities are exempt from continuous USDA inspection, provided that the meat is processed for the personal use of the individual who raised the animal or the owner of the animal at the time of slaughter. However, it is crucial that these plants adhere to basic sanitary standards. Meat from custom exempt plants is not for sale and must be marked "Not for Sale".

Key Legal Considerations:

Licensing and Regulation Compliance: Operators must obtain necessary licenses and adhere to regulations set by federal and state authorities.

Health and Safety Standards: It is essential to maintain health standards to prevent contamination, which involves proper sanitation, storage, and waste disposal.

Labeling Requirements: Any packaged meat should comply with labeling laws which include proper identification of products and any relevant health warnings.

Liability Risks:

Product Liability: Should non-compliance lead to foodborne illness, operators could face lawsuits.

Operational Liability: Failure to comply with occupational health and safety standards can result in fines or legal action.

Operators should consult legal experts to tailor their practices to current laws and reduce the risk of liability. Furthermore, insurance policies are advisable to mitigate potential financial impacts due to accidents or legal claims.

Future Directions in On-Farm Meat Processing

On-farm meat processing in Louisiana is poised to adapt through innovations that address current challenges in the industry. Mobile slaughterhouses are heralded as a game-changing solution, designed to alleviate the bottlenecks caused by processing capacity constraints. They offer flexibility to farmers by bringing processing services directly to the farm, hence reducing transportation stress on animals and potentially improving meat quality.

The integration of technological advancements is crucial for on-farm processors. Digital tools for tracking and managing livestock could streamline operations and ensure compliance with food safety standards. Investing in research and development will be essential to foster new methods of processing that can lead to greater efficiency and sustainability.

In terms of regulation, there's a trend towards more supportive policies that encourage small-scale processors. Potential regulatory reforms may include simplifying the certification process, providing guidance for compliance with food safety requirements, and expanding market access for on-farm processed meats.

Stakeholders are exploring innovative business models that may include:

Cooperative processing facilities: Shared resources and knowledge among local farmers.

Direct-to-consumer sales: Leveraging online platforms to market and sell products.

Finally, education and training programs are fundamental; they ought to empower producers with the necessary skills to safely and effectively operate on-site processing units. These directions show the commitment to create resilient supply chains that support local economies while meeting consumer demand for transparency and quality in meat production.