On-Farm Meat Processing, Butchering, and Slaughter in Massachusetts

A Comprehensive Guide

On-farm meat processing in Massachusetts presents an intersection of tradition and modernization in the agricultural industry. With farmers and niche producers seeking ways to streamline their operations, on-farm slaughter and butchering have become viable alternatives to conventional meat processing systems. This approach allows producers to maintain greater control over their products from pasturage to point-of-sale, ensuring that the overall quality of the meat is upheld according to their strict standards.

Massachusetts showcases a variety of on-farm meat processing facilities equipped to handle various livestock, including cattle and hogs. These enterprises strive to balance the demands of quality and efficiency, often embodying a farm-to-table ethos that is increasingly cherished in the market. By integrating slaughtering and butchering on-site, these farms can reduce transportation stress on animals, minimize environmental impact, and cater to consumers who prioritize transparency in their meat's origin and handling.

The state of Massachusetts imposes rigorous USDA standards that must be met for on-farm processing to ensure food safety and public health. Compliance with these regulations assures consumers that the meat products are inspected thoroughly, meeting national safety criteria. On-farm processors in the region, like Adams Farm Slaughterhouse, LLC in Athol, have set benchmarks for such operations, providing services for local farmers and mid-size companies while upholding the USDA's stringent inspection criteria. This supports not just the local agricultural economy but also serves as a blueprint for sustainable and ethical meat processing practices.

Fundamentals of On-Farm Meat Processing

On-farm meat processing in Massachusetts refers to the various methods and procedures involved in converting livestock to consumer-ready meat products on the premises of a farm.

Understanding On-Farm Processing

On-farm processing encompasses a range of activities from slaughtering animals to butchering and packaging meat products. In Massachusetts, there are specific regulations that define a custom poultry slaughterhouse which, according to state and federal law, is an establishment operating without the need for continuous inspection. Here, processing facilities only slaughter poultry for the use of the animal's owner. Conversely, the handling of red meat requires adherence to different regulations and processes, largely due to their distinct requirements for safety and quality control.

Benefits and Challenges of Local Meat Processing

The advantages of local meat processing are numerous, including the ability to support local economies and promote sustainable farming practices. Processing facilities located within a farm allow producers to maintain oversight of their product from start to finish, ensuring high-quality meat that adheres to animal welfare standards.

However, establishing an on-farm processing plant comes with challenges. Significant capital investment is often necessary to create a facility that complies with stringent food safety laws. Moreover, the public perception of slaughter and meat processing can present hurdles, as concerns over animal welfare and environmental impacts are increasingly influencing consumer behavior. Despite these challenges, those who have undertaken such ventures typically seek to enhance their financial resilience in an industry where price volatility is common.

Legal Regulations in Massachusetts

Massachusetts meat and poultry processors must navigate a complex landscape of state and federal guidelines to operate legally. Understanding the distinctions between state regulations and USDA requirements is crucial for compliance.

State and Federal Guidelines

State Regulations: In Massachusetts, the slaughtering and processing of meat and poultry are regulated under 105 CMR 500.030 and 105 CMR 500.031. These state regulations govern activities related to public health within the Commonwealth but do not detail provisions for game animals not typically considered under conventional meat and poultry categories. Processors need to be aware of the specific statutes and communicate with local and state authorities to guarantee operations are within legal parameters.

Federal Regulations: At the federal level, the USDA establishes regulatory frameworks for slaughter and processing activities. Any individual or entity engaged in butchering or meat processing must ensure these activities are permissible by law. Federal regulation allows for on-farm processing of poultry under certain exemptions. Producers who raise fewer than 20,000 chickens or 5,000 turkeys annually can process their birds on-farm, facilitating direct-to-consumer sales as well as sales to hotels, restaurants, institutions, and retail stores within the state.

USDA Facility Requirements

USDA-Inspected Slaughterhouse: Facilities that wish to engage in the interstate commerce of meat and poultry products must be USDA-inspected. The stringent facility requirements set forth by the USDA cover all aspects of the operation to ensure safety, hygiene, and proper handling of meat products intended for human consumption. To become a USDA-inspected facility in Massachusetts, processors must complete an application and adhere to federal construction, sanitation, and operational standards.

Licensing: For a facility to legally process meat and poultry, the Commonwealth of Massachusetts requires an official license. The application process includes submitting a form along with fee payments for each site. It is essential for processors to adhere to both state and USDA guidelines and complete all necessary steps for licensing to avoid legal pitfalls and guarantee the safety of their products.

Animal Welfare Considerations

When processing meat on-farm in Massachusetts, it is imperative to maintain high standards of animal welfare. There are clear regulations and strategies in place to ensure humane slaughter practices and to minimize stress for livestock at all stages of the process.

Humane Slaughter Practices

The cornerstone of humane slaughter practices is compliance with both federal and state laws, which mandate the use of methods that cause rapid unconsciousness followed by death without pain or distress. The Humane Methods of Slaughter Act is a critical federal statute that informs state regulations, ensuring livestock are insensible to pain before slaughter. For instance, captive bolt stunners are commonly used for cattle, which dispatches the animals swiftly and humanely.

In Massachusetts, on-farm slaughter must also be conducted in a facility that meets specific health and safety standards. This facility should be equipped with appropriate restraints designed to minimize movement and discomfort. The tools and equipment used are regularly inspected to ensure they remain in good working condition, further supporting a humane slaughter process.

Minimizing Stress for Livestock

Minimizing stress for livestock during the slaughter process is a concern directly addressing the well-being of the animals and the quality of the meat produced. Practices that reduce stress include:

Handling Practices: Gentle and calm handling to avoid eliciting fear or aggression in the animals.

Environmental Conditions: Providing a comfortable environment that is neither too hot nor too cold, protecting the animals from extreme temperatures through proper insulation or the use of cooling systems for hot weather and heating or enclosure for cold conditions.

Transportation: Reducing the distance animals are transported by processing on-farm, which decreases the overall stress experienced.

Familiarity: Keeping animals in familiar groups and avoiding mixing with unknown animals to prevent social stress.

Efficient Processing: Ensuring that the time between restraint and slaughter is as brief as possible.

By adhering to these practices, Massachusetts farmers can ensure animal welfare during on-farm meat processing, yielding high-quality meat while upholding ethical standards.

Slaughter and Butchering Techniques

Accurate and humane slaughtering and butchering techniques are vital for producing high-quality meat. From the handling of animals in the lead-up to slaughter to the final butchering process, adherence to proper procedures ensures safety, hygiene, and respect for the animal.

Cattle and Beef Processing

Cattle are typically stunned using either a captive bolt pistol or electrical methods to ensure instantaneous unconsciousness. Slaughtering of cattle must comply with welfare laws, and the process often includes hoisting the animals by their hind legs for blood draining, a crucial step for preventing meat spoilage and ensuring food safety. Following this, the carcasses are skinned, and the internal organs are removed carefully to minimize contamination. Butchering involves breaking down the carcass into wholesale cuts, with a clear understanding of the anatomy to ensure the best quality of beef, such as the brisket, rib, loin, and round.

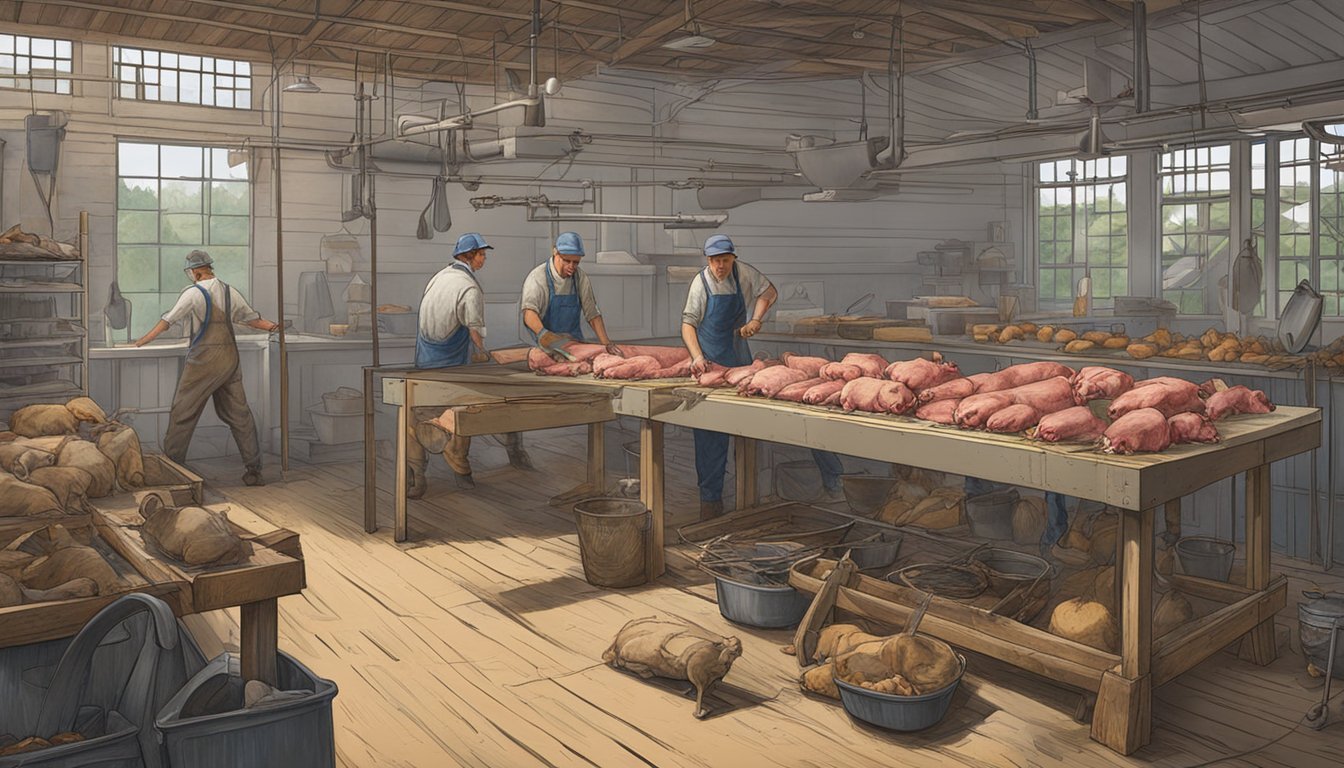

Pork and Hog Processing

The slaughtering of hogs is similar to that of cattle but with notable differences in equipment and techniques due to size and anatomy. Stunning is typically performed using electrical methods or carbon dioxide gas. After stunning, hogs are scalded to facilitate easier hair removal. They are then eviscerated, and the carcasses are split down the middle of the spine. Butchering hogs involves creating primary cuts like shoulder, loin, belly, and ham, followed by further processing into retail cuts or cured products like bacon and ham.

Sheep, Lamb, and Goat Processing

Sheep, lamb, and goat processing follow humane slaughtering techniques with a swift cut to the jugular and carotid artery for blood draining. This step, conducted with precision, ensures minimal stress to the animals and high-quality meat. Skinning and eviscerating the carcasses are performed with caution to avoid contamination from the fleece. During butchering, the carcasses are separated into standard cuts such as leg, loin, rib, and shoulder, which are then further processed or sold. The knowledge of meat science is applied to maximize yield and maintain the integrity of the meat.

Mobile Processing Units

Mobile processing units offer innovative solutions for on-farm meat processing, presenting a viable alternative for Massachusetts farmers to bypass traditional processing bottlenecks. These units streamline farm-to-market operations, embodying a blend of flexibility, efficiency, and regulatory adherence.

Advantages of Mobile Slaughtering

Mobile slaughtering units deliver several benefits:

Regulatory Compliance: They adhere to health and safety regulations, alleviating concerns about 'approved sources' as required by food codes.

Accessibility: Farmers gain direct control over the slaughtering process, thanks to the portability of these units.

Market Expansion: By enabling on-site processing, these units help farmers tap into niche markets and foster direct-to-consumer sales channels.

Reduced Stress for Animals: The on-farm slaughtering reduces animal stress associated with transportation to remote facilities.

Operational Set-Up of Mobile Units

Mobile units are typically structured into key functional sections:

Processing Area: Where the butchering occurs; equipped with necessary tools and sanitary facilities.

Cooling Area: For meat storage and temperature regulation post-slaughter to maintain freshness.

Mechanical Room: Houses the refrigeration unit, water tank, and generator, supporting the unit's self-sufficiency.

The trailers are designed to be self-contained, often featuring:

A 20kW onboard diesel generator

110V electrical system

Hot water plumbing

Insulation and lining package

Tandem axles for easy mobility

The capacity of these mobile slaughterhouses varies, with some able to process approximately 20-25 goats or sheep per day by a single butcher, and larger operations accommodating the processing of around 10 cows per day with two butchers.

Food Safety and Handling

In Massachusetts, the safety and quality of meat processed on farms are paramount. Strict adherence to sanitation standards and proper handling procedures is essential to prevent foodborne illnesses and ensure that meat products are safe for consumption.

Sanitation and Foodborne Pathogens

Maintaining a sanitary environment throughout the butchering process reduces the risk of contamination with foodborne pathogens. All surfaces, tools, and equipment must be regularly cleaned and sanitized before and after use.

Key steps include:

Routine Cleaning: Surfaces where meat is processed should be non-porous and cleaned with food-grade disinfectants.

Temperature Control: Bacteria proliferate between 40°F (4.4°C) and 140°F (60°C). Chilling the carcass promptly after slaughter is crucial.

Waste Water Management: Proper disposal of waste water and organic matter minimizes exposure to contaminants. Farms should have systems in place that align with local sewage treatment guidelines to handle waste water from the butchering process.

Carcass Handling and Storage

After slaughter, the carcass must be handled with care to prevent spoilage and contamination. This involves timely and proper cooling, storage, and transportation practices.

Critical considerations:

Cooling: Rapid cooling to below 40°F (4.4°C) inhibits bacterial growth. The carcass should be stored in a refrigeration unit regulated for temperature consistency.

Storage: Carcasses should be hung in a clean, dry, and refrigerated space to allow for proper airflow and maintained at a consistent temperature to ensure freshness.

Cross-Contamination: Separate processed meat from raw meat to prevent cross-contamination. Utensils and cutting surfaces should be dedicated to either raw or cooked products and not interchanged.

Infrastructure and Equipment Needs

For on-farm meat processing in Massachusetts, farmers must consider specific infrastructure and equipment. The investment and design must meet regulatory compliances and address both efficiency and animal welfare.

Essential Farm Processing Equipment

On-farm meat processing requires a range of specialized equipment. Key items include:

Stunning Devices: Crucial for humane processing, they should comply with animal welfare standards.

Scalding Tanks: Used to remove hair from carcasses, these tanks must sustain precise temperatures.

Dehairing Machines: These facilitate efficient hair removal post-scalding.

Evisceration Tables: A hygienic surface where internal organs are removed, critical for contamination prevention.

Chilling Facilities: Adequate refrigeration units to cool down the carcass immediately after processing to inhibit bacterial growth.

Cutting Tools: High-quality knives and saws are essential for butchering.

Equipment must be made from durable, food-safe materials, easy to clean, and designed to minimize the risk of contamination.

Designing an On-Farm Slaughterhouse

Designing an on-farm slaughterhouse entails careful planning to ensure the facility operates efficiently and meets health regulations.

Flow: The design should enable a seamless flow from reception to slaughter, processing, and storage, preventing cross-contamination.

Water Systems: Sufficient supply and drainage systems for cleaning and processing, including potable water for specific stages.

Waste Handling: Proper disposal systems for solid and liquid waste to maintain sanitary conditions and environmental standards.

Insulation: Good insulation is necessary to maintain temperature control within processing areas.

Ventilation: Adequate ventilation systems to manage odors and air quality, enhancing worker safety and product quality.

The design should be modular, allowing for future expansions or adjustments as production scales or regulations change.

Environmental Management

Effective environmental management in on-farm meat processing involves conscientious disposal strategies and the exploration of sustainable alternatives such as composting. These practices ensure that waste products do not pose a threat to the surrounding ecosystem.

Waste Disposal Solutions

Proper waste disposal is crucial for on-farm slaughter operations in Massachusetts. Facilities must comply with federal and state regulations concerning the treatment of waste water and solid wastes. This includes implementing:

Effluent treatment systems: These are designed to reduce pollutants in wastewater before release into the environment.

Solid waste management: Proper handling and disposal of non-compostable materials are enforced to prevent environmental contamination.

Given the significant volume of waste generated, facilities often turn to licensed waste management services to handle their disposal needs securely and in compliance with environmental regulations.

Composting as an Alternative

Composting represents a beneficial alternative for the management of organic waste from slaughter activities. When done correctly, it provides several advantages:

Reduces the volume of waste sent to landfills.

Transforms waste into valuable soil amendment products.

Facilities must ensure that composting processes are aligned with Massachusetts' Department of Agricultural Resources guidelines which dictate parameters for:

Aerobic conditions to accelerate decomposition.

Temperature maintenance to ensure pathogen destruction.

Odor control measures to minimize impact on neighboring areas.

Compost that is produced can then be utilized on-farm to improve soil fertility, thereby closing the nutrient loop sustainably.

Economic Aspects for Farmers

The economic implications of on-farm meat processing are vital for Massachusetts farmers, as they balance costs with potential market opportunities.

Cost-Benefit Analysis for Farmers

Farmers in Massachusetts who consider on-farm meat processing must conduct a thorough cost-benefit analysis. Initial costs include but are not limited to:

Capital investment for processing facilities and equipment.

Licensing and compliance with regulations.

Training for skilled labor.

On the other side of the ledger, benefits may include:

Reduced transportation costs: Farmers save on expenses associated with transporting livestock to distant processing facilities.

Higher profit margins: By processing on-site, farmers can bypass middlemen, selling directly to consumers or retailers.

Value-added products allow for diversified income streams.

Farmers must also consider opportunity costs and the impact of allocating time and resources to processing, which diverts from other farm activities.

Development of Meat Markets

The development of meat markets for smaller-scale livestock farmers hinges on strategic decisions impacted by on-farm processing.

Accessibility: On-farm processing gives farmers better access to local and niche markets, catering to customers who value locally-sourced meat.

Fair competition: Smaller meat markets enable farmers to compete against larger, more centralized entities, potentially leading to fairer pricing.

Resilience: By fostering a stronger local meat supply chain, farmers contribute to a more resilient agricultural economy in Massachusetts.

Farmers must stay informed on market trends and consumer demand, carving out a space in the meat market that aligns with their processing capabilities and economic objectives.

Community and Cooperative Models

Engaging local stakeholders, Massachusetts has fostered community-driven efforts to enhance on-farm meat processing through farmer cooperatives and nonprofit support. These models not only strengthen the local meat supply chain but also emphasize community engagement and sustainability.

Farmer Cooperatives and Networks

Farmer cooperatives play a pivotal role in streamlining the meat processing supply chain by pooling resources to overcome common barriers. For instance, the formation of cooperatives allows farmers to collectively own processing facilities, like the Bay Area Ranchers Cooperative, which operates a USDA-inspected mobile slaughter unit. This unit facilitates the processing of cattle, sheep, goats, and hogs.

Bay Area Ranchers Cooperative by the Numbers:

Animals Processed: Cattle, Sheep, Goats, Hogs

Facility: USDA-inspected mobile slaughter unit

Capacity: Capable of slaughtering and processing substantial quantities weekly

Through these cooperative models, they also bring together a network of farmers who share similar processing needs and market goals, enhancing their economic viability on a local and regional level.

Nonprofit and Community Support

Nonprofits and community initiatives are vital in supporting and sustaining the collaborative models between farmers and local meat processors. A significant role of these entities involves forming community investment funds that provide financing to farm and food businesses. By doing so, these nonprofits address broader social goals, such as increasing food access through programs like the CSA for low-income seniors and the Massachusetts SNAP-rebate program.

One approach to community-involved support has been a data-driven strategy to identify cost-effective solutions for regional meat supply challenges. Nonprofit and community support can reinforce cooperative efforts by facilitating necessary conversations and laying the groundwork for engagement among meat producers, processors, and local food advocates.

Innovation and Adaptation

Massachusetts has seen significant advancements in on-farm meat processing due to both innovative technologies and adaptive practices in response to recent challenges, such as the COVID-19 pandemic.

Pandemic Response and Resilience

In the wake of COVID-19, on-farm meat processors in Massachusetts demonstrated remarkable resilience by quickly adapting to the increased demand for local meat. The pandemic highlighted the meat processing bottleneck, constraining farmers' and consumers’ access to meat products. To counteract this, measures included expanding processing capacities and enhancing workforce training. Additionally, Massachusetts farmers have worked to expand poultry processing capabilities, given the rise in poultry consumption during the pandemic.

Emerging Technologies in Meat Processing

On-farm meat processors in Massachusetts are integrating emerging technologies to improve efficiency and product quality. Key innovations include:

Automated butchering lines reducing physical strain on workers and increasing precision in cuts.

Advanced packaging solutions, like vacuum sealing, to extend the shelf life of meat products.

These technological advancements not only foster better adaptation to market demands but also contribute to sustainable practices by reducing waste in the supply chain.

Case Studies and Examples

Within this section, readers will gain insights from specific instances of on-farm meat processing and butchering across various states, drawing upon both larger successful models and more intimate small farm operations.

Successful Models from Different States

In Wisconsin, a model case study involves mobile slaughtering units. These units, typically encompassed within a 26-foot box truck, can efficiently slaughter 25-30 beef and 30-40 hogs per week, addressing the critical bottleneck in the slaughtering process. In Colorado, ranchers have adapted to similar models where mobile units provide state-inspected services, ensuring that the meat is permissible for resale, which diversifies their revenue streams.

Nebraska's approach to meat processing involves fixed facilities that support local economies by processing and providing retail and wholesale markets with locally raised meats. Kentucky, and more specifically in Frankfort, processors have been known to create a collaborative environment where they act as the intermediary between farmers and restaurants, adjusting to market demands such as increasing the supply of local beef liver.

Small Farm Case Studies

Small farm operations have significant variances in their processing models. For instance, farms in the mountainous regions of Western North Carolina have exemplified retail exempt processing, where they specialize in local, pasture-raised meats without the need for state inspections for retail sales—a model that could be considered by Massachusetts farms.

The closely knit relationships within these communities often lead to a symbiotic ecosystem. Farmers and processors work together to utilize all parts of the animal, ensuring minimal waste and maximizing profitability. This cooperative behavior serves as a blueprint for small farms in Massachusetts looking to establish or refine their meat processing operations.

Promotion of Local and Pasture-Raised Meat

Massachusetts is charting a course in the promotion of local, pasture-raised meats through focused marketing strategies and consumer education. These efforts aim to enhance the market presence of high-quality, locally sourced meats and impart knowledge regarding their quality and benefits.

Marketing Strategies

Local meat producers in Massachusetts deploy a variety of marketing strategies to elevate the presence and appeal of pasture-raised meat. By highlighting the origin and sustainable practices of local farms, they are able to target consumers who value transparency and environmental responsibility.

Farmers Markets: Producers commonly participate in community farmers markets to directly engage with consumers.

Social Media Campaigns: They utilize social media platforms to share stories, images, and testimonials that showcase their commitment to raising animals humanely on pastures.

Collaborations with Local Chefs: Producers collaborate with restaurants to feature locally-sourced dishes, thus tapping into the foodie culture and increasing visibility.

Consumer Education on Meat Quality

Educating consumers on the nuances of meat quality is critical to fostering an appreciation for pasture-raised products.

Taste Tests: Organizing taste test events allows consumers to experience the flavor profile of pasture-raised meats firsthand.

Informational Workshops: Hosting workshops that explain the health and environmental benefits of pasture-raised meats, including the absence of added hormones and antibiotics, helps to inform purchasing decisions.

Quality Control Transparency: Producers are transparent about their quality control practices, ensuring customers understand the rigorous standards pasture-raised meats must meet.

Conclusion

On-farm meat processing in Massachusetts reflects an evolving sector with several key developments to note. The state has historically had a limited number of USDA-inspected slaughterhouses, which has posed challenges for local livestock producers. However, recent efforts to increase this number indicate a positive trend toward supporting the regional agriculture economy.

Massachusetts farmers have demonstrated resilience and innovation by forming consortia to establish more accessible processing facilities. The anticipated opening of a new slaughterhouse in Westport stands testament to this collaborative approach. These efforts are not only a response to market demands but also serve to enhance financial stability among producers.

Regulation compliance remains critical, as does the continuous need for capital investment to keep operations running smoothly. Producers must navigate federal and state laws while considering public perception and the ecological impacts of their activities. Moving forward, the role of technology and sustainable practices will likely become even more pertinent in ensuring the efficiency and environmental compatibility of on-farm processing operations.

The future outlook for Massachusetts suggests continued growth in this sector, with an emphasis on meeting the needs of local farms and addressing concerns over meat supply chains. Producers are increasingly recognizing the value of controlling the processing aspect of their businesses, therefore contributing to the strength and resilience of the local agricultural framework.